Yongte Wood Plastic Machine: Integrated WPC Production Solutions for Global Manufacturers

As a leading global supplier of plastic & wood-plastic composite (WPC) equipment, Qingdao Yongte Plastic Machinery specializes in Wood Plastic Machine series – including WPC door making machines, WPC board production lines, WPC profile extruders, and turnkey WPC manufacturing systems. Our equipment combines high automation, eco-friendly processing, and durable performance, helping clients from 50+ countries (Europe, Southeast Asia, Africa, South America) build efficient WPC production businesses.

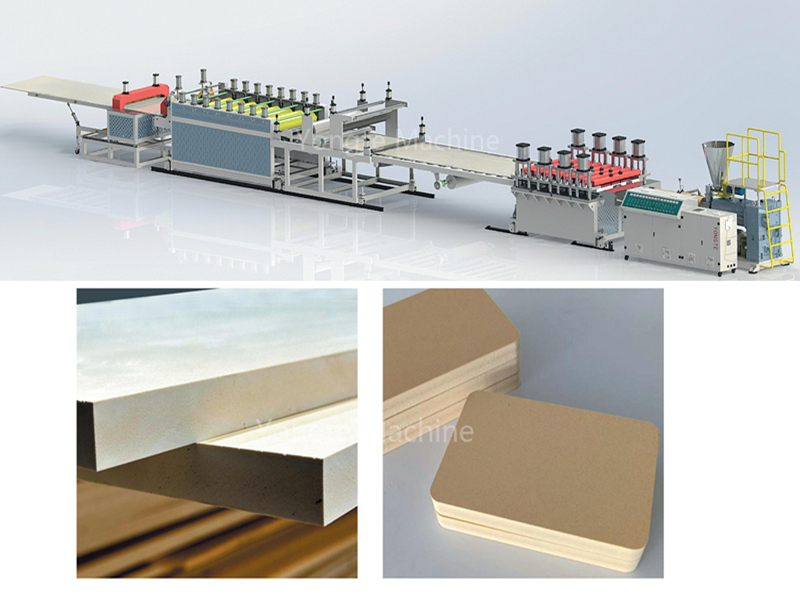

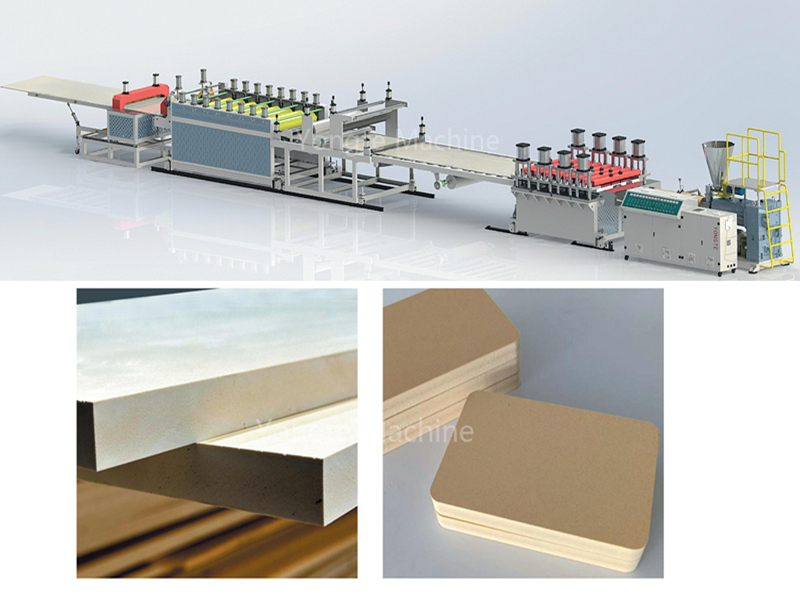

We offer full-series Wood Plastic Composite Machinery to meet diverse WPC product manufacturing needs – from raw material mixing to finished product packaging, each line is tailored for stability and cost-effectiveness.

-

Full-process Automation: Integrates raw material mixing, WPC panel extrusion, PUR hot melt lamination, CNC 5-side engraving, double-side sanding, and automatic cutting – reduces labor cost by 60% vs traditional equipment.

-

High Customization: Supports door panel widths (800-1300mm), thicknesses (5-30mm), and surface finishes (wood grain PVC film, CPL, leather); custom patterns (floral, minimalist) via high-speed CNC (6000-12000 rpm).

-

Eco-friendly & Durable: Uses low-noise (≤75dB), energy-saving motors (22-45KW); finished WPC doors are moisture-resistant, termite-proof, and meet ISO/CE standards.

-

Multi-material Adaptation: Processes WPC foam boards, solid WPC boards, and anti-slip WPC flooring – raw materials (wood powder + PVC/PE resin + CaCO3) with cost-saving formulations provided.

-

Stable Extrusion: Bimetallic screws + SKD-61 coated barrels ensure uniform plasticization; vacuum calibration system (6-12m length) guarantees board flatness (deviation ≤0.5mm/m).

-

High Efficiency: Max board width 1220mm, thickness 3-50mm; automatic stacking (6m platform) reduces product damage rate to <1%.

-

Versatile Production: Manufactures WPC door jambs, edge covers, window sills, and decorative profiles – mold customization available for 500+ profile shapes.

-

Precision Control: ABB inverters + Omron temperature controllers (160-200℃) ensure consistent profile dimensions; haul-off machine (2.4m effective length) with double caterpillars prevents deformation.

-

Low Maintenance: Key components (heaters, screws) have 5000+ hours service life; dust-collecting cutting machine keeps workshop clean.

Our Wood Plastic Machine series stands out for solving manufacturers’ core pain points:

-

Turnkey Convenience: "One-stop" solution from equipment design to on-site commissioning – includes raw material formulas, staff training, and 24/7 technical support (no need for third-party coordination).

-

Cost-effectiveness: Energy-saving design reduces power consumption by 15% vs industry average; free warranty (2 years for extruders/motors) lowers maintenance costs.

-

Global Compliance: All machines meet CE, ISO 9001 standards; power supply (380V/50Hz, 220V/60Hz) and safety systems customizable for local markets.

-

Eco-friendly Advantage: Zero waste discharge during processing; WPC products made by our machines are 100% recyclable – align with global green building trends.

Yongte Wood Plastic Composite Machinery serves diverse industries, matching global market demands:

-

Construction: WPC doors, flooring, wall panels, window frames (residential/commercial buildings).

-

Furniture: WPC cabinet boards, wardrobe panels, table tops (moisture-resistant for kitchens/bathrooms).

-

Outdoor: WPC decking, garden fences, park benches (UV-resistant, weather-proof).

-

Industrial: WPC partition boards, warehouse pallets (high load-bearing, anti-corrosion).

As a trusted Wood Plastic Machine Manufacturer in China, we provide lifelong value for clients:

-

Pre-sales: Free factory visits, customized production line design (based on your capacity/ product needs).

-

In-sales: On-site installation (7-15 days), operator training (5-7days, hands-on practice).

-

After-sales: Lifetime technical support (online via WhatsApp/Zoom, on-site service within 48 hours for urgent issues); spare parts warehouse in Europe/Southeast Asia for fast delivery.

Whether you’re a startup planning to enter the WPC market or a large enterprise expanding production, Yongte has the right Wood Plastic Machine for you.

👉 Get a Free Quote: Send your product type (door/board/profile), capacity needs, and target market – our team will reply with a customized solution within 24 hours.

Hot Tags: Yongte Wood Plastic Machine, China, Manufacturer, Supplier, Factory, Buy, Quality, CE, Price