CE certified WPC door machine line - High efficiency (350-400kg/h), excellent quality, eco-friendly & automatic. we supply turnkey project with full equipment & global after-sales.Yongte is top wood plastic door extrusion line manufacturer located in China.

Yongte Wood Plastic WPC door machine line is a specialized production line designed for manufacturing wood plastic composite (WPC) doors using PVC resin and wood materials. This production line encompasses all stages of wood plastic door production, including mixing, extrusion, molding, as well as subsequent processing and assembly. It offers a one-stop production solution, characterized by its efficiency, flexibility, and eco-friendliness.

Yongte Wood Plastic WPC door machine line is evident in its wide range of applications. It can be used to produce various types of wood plastic composite doors, such as interior doors, exterior doors, and even special-purpose doors for specific environments like hospitals or schools. The production line's flexibility allows for customization in terms of door size, design, and color, meeting the diverse needs of different customers and markets. Moreover, its eco-friendly nature makes it an ideal choice for those looking to reduce their environmental impact while still maintaining high production standards.

Yongte is professional manufacturer for complete Wood Plastic WPC door machine line with high quality and great service. we supply the WPC door turnkey project according to customer's requirements, including wood powder making machine, WPC mixing machine, WPC door profile extrusion machine, WPC door panel extrusion machine, WPC door profile molds, WPC door panel molds, lamination machine, engraving machine, cutting machine, sanding machine and other auxiliary equipment.

Wood-plastic door turnkey production line mainly includes the following manufacturing process:

The WPC door raw material mainly including wood powder, PVC resin, additives and so on. These raw materials are accurately matched and mixed to form wood-plastic composites. we supply wood powder making machine to process wood chips, sawdust, straw, husk into wood powder.

The raw materials shall be mixed together by our hot and cold mixer according to our detailed formulation for making high quality and low cost WPC door panel and WPC door frame products.

because the formulations for WPC door profile extrusion and WPC door panel extrusion are different, so two sets of mixers shall be needed.

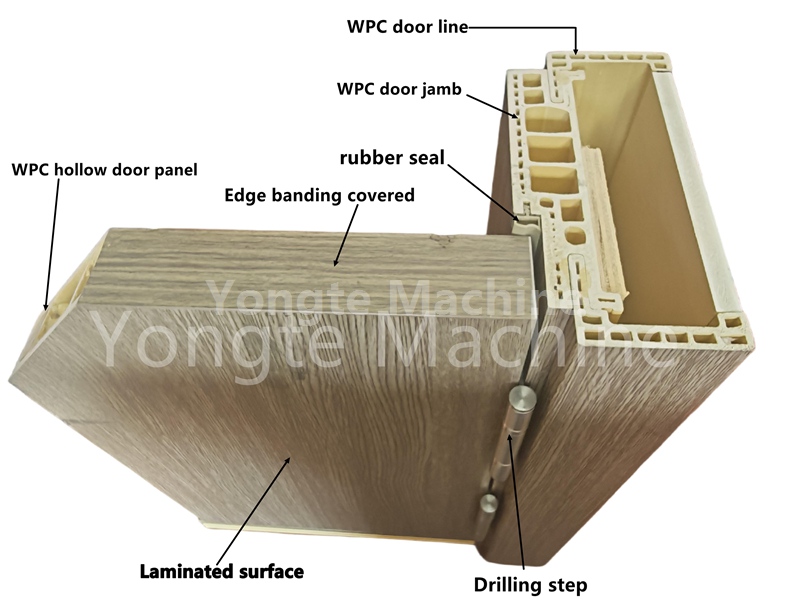

this machine will make the WPC door profiles (such as WPC door frame, WPC door jamb, WPC wall line) from the mixed wood-plastic composite material, it is a complete extrusion line including auto feeder, high effiency conical twin screw extruder, high speed vacuum calibration and cooling system, stably pull off tractor, automatic cutting length equipment, and auto product stacker. various of WPC door profiles with different dimensions can be made by this line by changing mold.

A big extrusion line which can make max.1200mm width WPC door panel is equipped for making WPC hollow door panel or WPC solid door panel as per customer's needs, the complete WPC door panel extrusion line includes auto feeder, high effiency conical twin screw extruder, fast vacuum calibration and cooling system, stably pull off tractor, automatic cutting length equipment, and auto product stacker. various of WPC door panels with different dimensions can be made by this line by changing mold.

WPC door panel sanding machine is used for polishing the WPC door panel surface to make it more flat, more smooth, and little roughness for increasing the adhesion of glue. we have different type of sanding machine to match different surface finsihing requirments.

6,Cutting length, width and angle for the WPC door panel and WPC door frame

Our precision cutting machine is used for cutting the length and width of WPC door panel as per market needs, it also can be used for cutting length and angle of WPC door profiles. It ensures high precision cutting with minimal material wastage. The machine is equipped with a sharp and durable blade that can easily handle different thicknesses of WPC materials. Additionally, it has a user-friendly interface, allowing operators to set the desired cutting parameters quickly and accurately. Its stable structure also guarantees smooth operation during the cutting process.

7, Drilling locks and hingle steps:

Automatic drilling machine is used for drilling locks and hingle steps on the WPC door panel, it is an automatic equipment with programmed system control which can follow all the functions, such as lock holes, hingle steps, cat eye holes, handle holes.It features high precision drilling to ensure accurate hole positions, which is crucial for the proper installation of locks and hinges. The machine is equipped with a user - friendly control system, allowing operators to easily set parameters according to different drilling requirements.

8, Engarving required designs:

Automatic CNC engraving machine is used for carving designs on the WPC door panel, it also can cut holes for install glasses on the door panel. The high precision CNC system ensures detailed and accurate carving, meeting various design requirements from simple patterns to complex artworks. Its automatic tool changing function improves production efficiency and reduces manual operation errors. it has advantages of easy operation, high automatic, low maintenance cost.

9, Laminating decoration film:

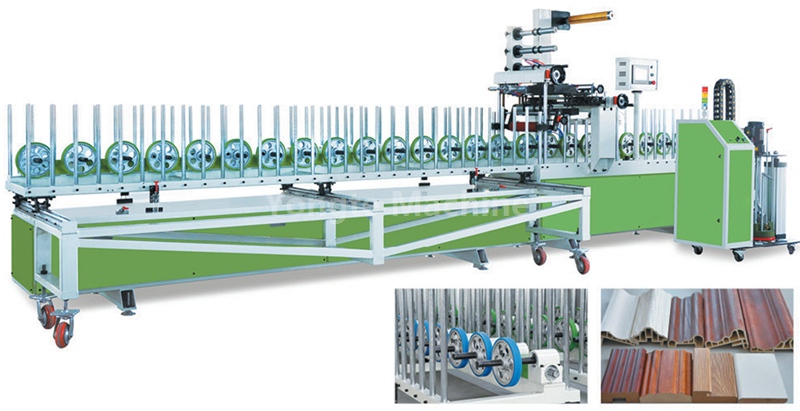

WPC door profile PUR lamination machine: it is used for laminating decoration film on the WPC door profiles. Utilizing advanced PUR hot melt adhesive technology, the machine ensures strong, durable bonding with excellent resistance to heat, moisture, and aging, delivering a high-quality, long-lasting finish for WPC door products. It supports a wide range of lamination materials including PVC film, decorative paper, wood veneer, CPL (Continuous Pressure Laminates), and leather.

WPC door panel PUR lamination machine: it is used for laminating decoration film on the flat WPC door panel(without engraving), Utilizing advanced PUR hot melt adhesive technology, the machine ensures strong, durable bonding with excellent resistance to heat, moisture, and aging, delivering a high-quality, long-lasting finish for WPC door products. It supports a wide range of lamination materials including PVC film, decorative paper, wood veneer, CPL (Continuous Pressure Laminates), and leather.

Vacuum lamination machine: it is designed for laminating PVC decorative films onto WPC door panels with shaped surfaces (post-CNC engraving). It needs workers to spraying cold glue on the door panel before lamination.

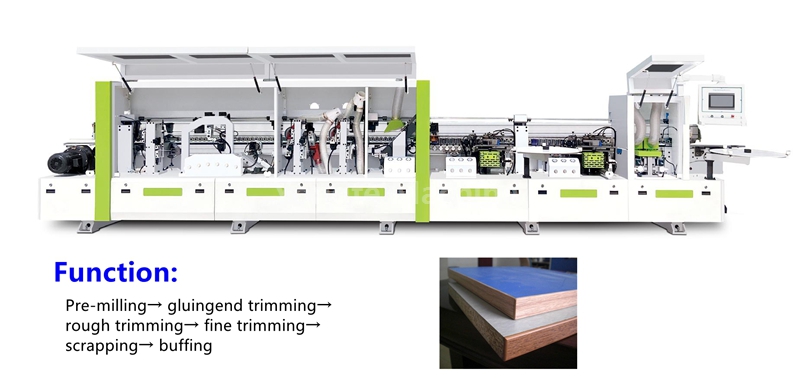

10, Edge band covering:

The WPC door panel sides can be covered by edge band to ensure the laminated film can be better fixed without peel off, and also the hollow cutting section can be fully covered. we supply automatic edge band covering machine with full functions, It automatically trims excess edge banding material to achieve a seamless finish, enhancing the door's aesthetic appearance and structural integrity. The machine features precise temperature control systems to ensure strong adhesion between the edge banding and door panel, with adjustable speed settings to accommodate different door sizes and material thicknesses.

assemble the processed door panels with other accessories and package them for transportation and installation.

With people's demand for environmental protection and beauty, wood plastic door as a collection of environmental protection, beautiful, practical in one of the new building materials, its market demand will continue to expand. Therefore, the wood-plastic door turnkey production line has broad application prospects. At the same time, with the continuous progress and innovation of production technology, the performance and efficiency of the production line will be further improved, providing strong support for the rapid development of the wood-plastic door industry.

Yongte WPC door machines utilize advanced production technology and equipment to achieve efficient and continuous production. Compared to traditional methods, they significantly enhance production efficiency and can accommodate large-scale production demands.

Yongte WPC door machines ensure consistent quality of wood-plastic profiles through precise control systems and stable production processes. Additionally, the equipment can be adjusted to meet various production requirements, ensuring product diversity.

As an environmentally friendly building material, the production of wood-plastic profiles fully embraces the concept of sustainability. Yongte WPC machines incorporate advanced energy-saving technologies, effectively reducing energy consumption. Moreover, they facilitate proper disposal of waste generated during production, minimizing environmental impact.

Yongte WPC doors machines feature automated control systems, making operation straightforward. Operators can learn to manage the equipment with minimal training. Furthermore, the maintenance and management of the machines are relatively simple, which helps to lower operating costs.

The wood-plastic profiles produced by Yongte WPC door machines are versatile and can be utilized in multiple fields, including construction, furniture, and gardening. Their superior performance and eco-friendly attributes ensure a wide range of market applications.