Yongte Seepage Irrigation Pipe Making Machine can recycle and process waste tires into rubber irrigation pipes, also known as rubber nanotubes. After years of research and multiple trials, Yongte has developed a mature formula for producing nanorubber tubes. The rubber tubes produced have a uniformly distributed and well-connected network of nanoscale pores, ensuring efficient water permeation and effective filtration of impurities. These rubber tubes are widely used in agricultural irrigation systems, buried infiltration pipes, and pond oxygenation systems.

Yongte Seepage Irrigation Pipe Making Machine using waster rubber as raw material

I, Description of Seepage Irrigation Pipe Making Machine:

Yongte's Rubber Seepage Irrigation Pipe Making Machine can recycle and process waste tyre into rubber irrigation pipe, also known as rubber nano tubes. After years of research and multiple trials, Yongte has developed a mature formula for producing nanorubber tubes. The rubber tubes produced have a uniformly distributed and well-connected network of nanoscale pores, ensuring efficient water permeation and effective filtration of impurities. These rubber tubes are widely used in agricultural irrigation systems, buried infiltration pipes, and pond oxygenation systems.

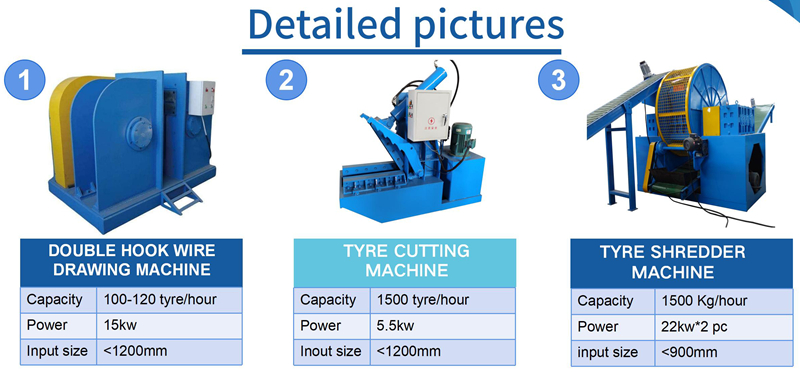

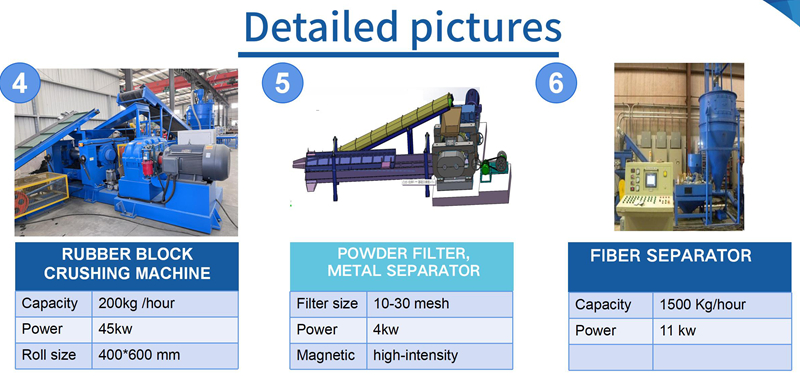

II, Details of Seepage Irrigation Pipe Making Machine

2.1, machine list and capacity

|

NO. |

Machine |

Unit. Capacity |

|

1 |

Rubber Powder Making machine: it will recycling the waste rubber tyre into rubber powder, it including functions of steel wire taking out, rubber tire cutting, shredding, crushing and grinding process. |

500 kg/h. 8 hours working |

|

2 |

Material Mixing machine: it will mix the necessary material according to our formula |

500 kg/h. 8 hours working |

|

3 |

rubber seepage irrigation hose extrusion line: it will extrusion the mixture material and mold into required diameter, and cooling the rubber hose, then winding the rubber hose into rolls. the general diameter is 9-32mm |

50-60kg/h 24 hours working You can equip 4-6 lines to get capacity of 300kg/hour for a complete project |

2.2, Machine pictures of rubber seepage irrigation hose making machines

III, Advantages of rubber seepage water pipe:

1, High permeability efficiency: the nanoscale pores are uniform, the permeability rate is increased by 2-3 times, and it is stable for a long time

2, Strong anti-clogging ability: the nanoscale pores allow water molecules to pass through, while blocking larger particles such as silt and microorganisms (similar to the "molecular sieve" effect), reducing the risk of blockage.

3, Long service life: through the combination of rubber and PE materials, the service life of rubber seepage pipe can reach 10-15 years, aging resistance is significantly enhanced

4, Low installation and maintenance cost: simple installation, plug in the connector to use, can be bent and rolled up, not easy to block, maintenance free cycle is long, the comprehensive cost is reduced by 40%-60%

5, Good environmental performance: the rubber seepage pipe can be produced from recycled waste tires, and can be recycled for many times, which is very economical and environmentally friendly.

The core advantage of rubber nano seepage pipe lies in their nano-scale material structure and permeation mechanism, which effectively address key challenges in traditional irrigation methods like flood irrigation and conventional drip irrigation—such as water waste, soil degradation, and low crop absorption efficiency. This breakthrough achieves the "precision, efficiency, and ecological sustainability" goals of irrigation. The advantages can be analyzed from three dimensions: material properties, irrigation mechanisms, and agricultural application value.

Core advantages: "Differentiated performance" brought by nanostructures

The core of the nanoscale seepage pipe lies in its wall construction using nano-scale porous materials (such as nano-ceramic composite pipes and nano-modified plastics). These materials typically feature pore diameters ranging from 1 to 100 nanometers, perfectly meeting the essential requirements —— of agricultural irrigation. They not only enable precise moisture control but also filter impurities and protect soil. The specific performance characteristics are as follows:

|

Performance dimension |

Characteristics of nanoscale water pipe |

Defects of traditional irrigation methods (flood irrigation/ordinary drip irrigation) |

|

Penetration accuracy |

The pores are small and uniform (nano scale), and the water is released slowly in the form of "capillary osmosis", avoiding local water accumulation |

Overdrip: Water concentration and infiltration can easily lead to deep leakage; ordinary drip irrigation: large nozzle diameter (millimeter level) is prone to "uneven dripping" due to water pressure fluctuations |

|

Antiblockade capability |

Nanopores can filter the silt and microorganisms (such as algae) in water, reducing pipeline blockage (the traditional drip irrigation rate is over 20%, nanotubes can reduce to less than 5%) |

Ordinary drip irrigation: The drip head is easy to be blocked by mud and fertilizer residue, which requires frequent flushing and high maintenance cost |

|

Weather resistance/ durability |

Nanomaterials (such as nano-silica modified plastics) are resistant to uv and soil corrosion (life up to 8-10 years in acid and alkali environment) |

Ordinary PVC drip irrigation pipe: easy to be aged by ultraviolet light and corrosion by soil salt, the life is only 3-5 years |

|

thermal adaptability |

Some nanocomposite tubes (such as nanotube reinforced tubes) can adapt to the temperature difference of-10℃~60℃, avoiding freezing and softening at high temperature |

Ordinary plastic pipe: easy to crack at low temperature, easy to deform at high temperature, need additional insulation/anti-sunshine measures |

compared with traditional irrigation: rubber nano seepage pipe are better with long-term economic benefits

Although the initial purchase cost of nano-permeable pipe is higher than that of ordinary drip irrigation pipe (about 20-30%), its comprehensive cost is lower in the long term (5-8 years cycle):

3.1 Water saving cost: based on the average annual irrigation water demand of 300 cubic meters per mu of field crops, nanotubes save 100-150 cubic meters of water per mu per year compared with flood irrigation. According to the agricultural water price of 1 yuan/cubic meter, the annual water saving cost per mu is 100-150 yuan.

3.2 Maintenance cost: ordinary drip irrigation pipe needs to be dredged and replaced (blocked pipe/aging) 1-2 times per year, and the maintenance cost is about 50 yuan per mu; nano pipe has low blockage rate and long life, and the annual maintenance cost is only 10-20 yuan, saving 40 yuan per mu per year.

3.3 Increased yield income: precision irrigation + soil protection can increase crop yield by 10%-15% (for example, corn yield per mu increased by 50-80 kg, at the market price of 2 yuan/kg, annual income per mu increased by 100-160 yuan).