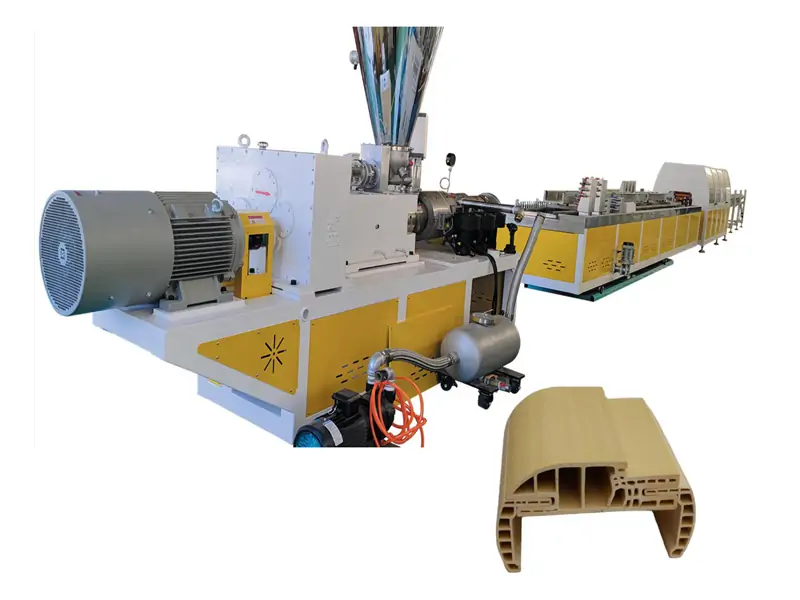

Yongte WPC door frame machine is specifically designed for manufacturing PVC WPC door frame profiles, it features high production capacity, superior product quality, user-friendly operation, energy efficiency, and straightforward maintenance.

Yongte high-capacity WPC door frame machine line has many advantages such as high efficiency, high quality, energy saving and environmental protection, easy operation, flexible adaptability, low maintenance cost, safety and reliability, continuous innovation and professional services. the complete WPC door frame machine including auto feeder, conical twin screw extruder, die and mould, calibration and cooling table, pull off and cutting machine, product stacker. the production line can be used for making different WPC profiles by changing mold, such as WPC door frame, WPC door jamb, WPC wall panel, ceiling panel, skirt panel, decoration profiles..

Model

YT200

YT300

Max Panel Width

200mm

300mm

Extruder

SJSZ51/105 conical twin-screw extruder

SJSZ65/132 conical twin-screw extruder

Main Motor Power

22 kW

37 kW

Output Products

Small PVC door profiles, PVC door lines

PVC door frames, PVC door jambs

Raw Materials

PVC resin, CaCO₃, wood powder, and chemical additives

Screw Material

38CrMoAl with bimetallic coating

Barrel Material

38CrMoAl with SKD coating

Extrusion Capacity

150 kg/h

200 kg/h

Machine Length

22 meters

25 meters

Inverter Brand

ABB

ABB

Contactor Brand

Siemens

Siemens

Temperature Controller Brand

Omron

Omron

Calibration Table Length

6 meters

8 meters

Pull-off Tractor Width

1800 mm

2400 mm

Product Stacker Length

6000 mm

6000 mm

Quality Certification

CE Certified

CE Certified

By changing mold, the Yongte high capacity WPC door frame machine can make different WPC door profiles with different sizes and shapes, Yongte can help the customer to design the door frame system as per their market demands.

The WPC door profile high capacity extruder adopts high effective conical double screw extrusion system, it equip with auto feeder, high effective driving system, high capacity and high wearing screw, infrated heating system. the main motor power is 45KW equip with ABB inverter control.

High capacity cooling and calibration machine: made of stainless steel, including stainless steel frame and sound insulation film with noise reduction. The proprietary stainless steel frame as the water circulation system keeps the internal pipe system, and the unique design structure and reasonable layout can prevent the shaking during the production process and ensure the quality of the product

1, length of table: 11.8meter

2, cooling method: water and vacuum

3, vacuum pump: 7 sets, body made by 304 stainless steel

4, water pump: 1 set, all connected elbows are made by stainless steel

Tractor and cutter machine

It consists of two mechanical units assembled on the same robust frame and has an optional film covering device. The lower traction track is a fixed structure, and the upper traction track is mounted on a high-precision guide plate, and the appropriate pressure can be adjusted. The transmission system of the upper and lower tracks is equipped with two maintenance-free AC frequency conversion motors, which are directly connected with the reducer. Special and quickly replaceable crawler press block. Cutting saw is equipped with maintenance-free horizontal moving cutting device, profile cutting saw synchronized with traction capacity, using one-way bearing and chain control, saw blade using pneumatic control; cutting length is controlled by high-precision encoder, and equipped with a high-power chip suction device

The product stacker 6000mm long; consists of a square tube frame and stainless steel flip table with signal from the cutting length counter. The flip table can be adjusted to the height of the extrusion centerline.

1. Language: English or customized

2. The main electrical control components are Siemens or Schneider products.

3. The main motor is Siemens Beide motor, 45KW, with ABB inverter control

4. The feeder capacity regulating device is ABB frequency converter.

5. Omron intelligent temperature control instrument

6. Electrical control cabinet control includes: temperature control system; drive system, pull off system, cooling system.

7. Heating is controlled by a temperature controller, solid-state contactor, and high-temperature resistant wires.

1. High-efficiency production: Yongte wood-plastic door profile high-capacity extrusion line adopts advanced production processes and technologies, which greatly improves production efficiency. For companies pursuing production capacity and efficiency, this is undoubtedly the biggest selling point.

2. Quality assurance: Products undergo strict quality control and multiple inspections to ensure that the quality of the wood-plastic profiles produced is stable and reliable.

3. Energy saving and environmental protection: Yongte WPC door profile high capacity machine was designed with environmental protection factors in mind, effectively reducing energy consumption and pollution during the production process, and helping companies achieve green production.

4. Easy to operate: Yongte high capacity WPC door frame machine is simple to operate and does not require complicated training. Employees can get started quickly, which reduces the company's training costs and time costs.

5. Flexible adaptation: The high-capacity extrusion line can adapt to the production of wood-plastic profiles of different specifications, providing enterprises with more production options.

6. Low maintenance costs: Yongte WPC door profile high capacity equipment structure is reasonably designed and worn parts are easy to replace, reducing the company's maintenance costs.

7. Safe and reliable: Yongte high capacity WPC door profile equipment is equipped with complete safety protection measures to ensure employee safety and equipment stability during the production process.

8. Continuous innovation: We continue to carry out technological research and development and innovation to ensure that the wood-plastic profile high-capacity extrusion line is always at the forefront of the industry.

9. Professional services: We provide professional pre-sales consultation, in-sales service and after-sales support to ensure that customers receive timely help and solutions during use.