Yongte innovative rubber irrigation pipe machine is designed to efficiently produce high-quality and low cost rubber irrigation pipes from rubber wastage, which are crucial for modern farming practices. Its advanced technology ensures consistent pipe dimensions, excellent durability, and optimal water flow, making it an ideal solution for farmers looking to enhance their irrigation systems.

Yongte is professional leading manufacturer located in China for rubber irrigation pipe machine. After years of equipment optimization, formula development, and experimentation, Yongte has successfully produced the rubber irrigation pipe machine for making microcellular foam rubber irrigation pipes with built-in capillary pores. This capillary structure enables uniform water distribution along the pipe length, ensuring every part of the field gets adequate water. The fine rubber pores act as tiny channels, regulating flow to prevent waterlogging or dry spots. This innovative design not only conserves water but also boosts crop growth by maintaining consistent moisture levels—critical for healthy plant development. The Yongte rubber irrigation pipe machine efficiently transforms scrap rubber into high-performance pipes through a seamless automated process. It reduces labor costs and errors, cuts energy consumption by 30% compared to older methods, and features a modular design for rapid material changes and maintenance. By accommodating recycled rubber powder, it decreases waste and raw material expenses, ensuring a consistent nano-pore structure for precise irrigation, drainage, or aquaculture—durable and cost-effective for modern water management..

|

Parameter |

Specification |

|

Machine name |

Yongte Rubber rubber irrigation pipe machine |

|

Material |

Rubber powder, PE granules, Chemical additives |

|

Product |

Irrigation pipe, micro nano pipe, seepage pipe, soaker pipe, oxygen pipe |

|

Pipe Diameter Range |

9-32mm (adjustable) |

|

Production Speed |

3-10 m/min (adjustable) |

|

Output Capacity |

80-120kg/h |

|

Extruder Model |

SJ65 Single screw extruder |

|

Main motor power |

22kw Innovance servo motor with speed control |

|

winder |

Auto winder, single position or double position optional |

|

Installation power |

Around 60kw (including heating power and auxiliary equipments) |

|

Power consumption |

Around 20kw |

|

Machine length |

16 meters |

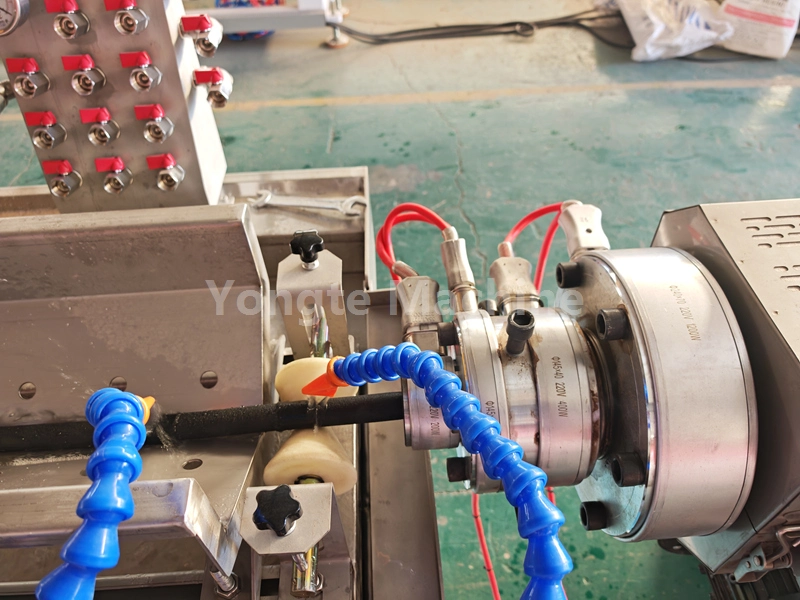

1. High-Efficiency Extrusion System:

(1) The extruder is custom-engineered for processing recycled rubber powder and PE granule blends.

(2) Its screw features a specialized foaming design that creates uniformly distributed nanoscale pores in the rubber pipe, ensuring consistent permeability and structural integrity.

2.Rubber Irrigation Pipe Mold:

(1) A specialized extrusion tool for the continuous production of rubber nano pipes from recycled rubber powder using nano foaming technology.

(2) The nano holes are uniformly distributed, ensuring good foaming.

3. Fast Cooling Tank:

(1) Constructed entirely from 304 stainless steel

(2) this 6-meter water cooling tank provides rapid, uniform cooling to stabilize the pipe structure and maintain dimensional accuracy post-extrusion.

4. Rubber Pipe Traction Machine:

(1) Equipped with double belt traction

(2) the machine ensures stable, consistent pulling of rubber pipes for continuous and stable production.

5. Rubber Pipe Winder:

(1) An optional single-position or double-position winder with automatic tension control for consistent, damage-free coiling of rubber pipes.

(2) The winder can coil the rubber pipes into rolls with a customized diameter and width.

(3) Equipped with automatic cable laying and precision automatic meter-counting functions, the machine triggers an automatic alarm upon reaching the preset winding length.

6. Electric Control System:

(1) Our electrical components employ internationally acclaimed high-quality brands, such as ABB frequency converters

(2) Siemens and Schneider contactors

(3) Omron temperature controllers

(4) Siemens PLC control systems

(5) Innovance servo motors.

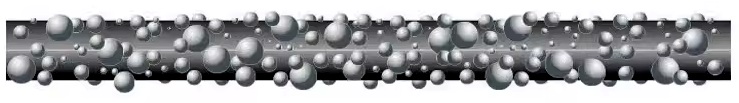

The irrigation pipe, constructed from resilient recycled rubber, incorporates minuscule capillaries within its structure. Upon connection to a water supply, the water is gradually released through these capillaries, a process facilitated by the pressure exerted by the water. The most advantageous aspect of this system is its exceptional water conservation capability. By positioning the drip pipes adjacent to the plants' growth areas, the water remains in proximity to the roots for an extended period, thus preventing overwatering and minimizing the wastage of valuable water resources through subterranean runoff. This irrigation method proves highly effective for a variety of applications, including lawns, vegetable gardens, and flower beds, and is particularly adept at providing a precise and gentle watering regimen for rows of plants.

The micro-porous, water-permeable irrigation pipe, created using an innovative micro-porous extrusion foaming technique, effectively prevents the occlusion of its tiny openings. This highly precise irrigation system is designed to conserve water while ensuring plants receive an adequate supply of nutrients. It eliminates areas where water distribution is inadequate and stops negative pressure suction when the water supply is deactivated, thereby preventing the blockage issues commonly associated with traditional drip irrigation emitters. Installation is straightforward, requiring only the connection to a polyethylene pipe. In terms of water conservation, this system utilizes merely one-sixth of the water typically consumed by conventional flood irrigation methods. Furthermore, the drip irrigation system facilitates the integration of basal and top-dressing fertilizers directly into the irrigation water, minimizing nutrient loss due to gradual seepage. Consequently, crops benefit from uniform absorption of both water and nutrients, significantly enhancing the efficiency of fertilizer application.

1. High Permeability Efficiency: The uniform nanoscale pores enhance the permeability rate by 2-3 times and ensure stability over an extended period.

2. Strong Anti-Clogging Ability: The nanoscale pores permit the passage of water molecules while effectively blocking larger particles, such as silt and microorganisms, (due to a mechanism similar to the "molecular sieve" effect. This significantly reduces the risk of blockage.

3. Long Service Life: The service life of rubber seepage pipes can reach 10-15 years through the combination of rubber and PE materials, with significantly enhanced aging resistance.

4. Low Installation and Maintenance Cost: Simple installation with a plug-and-play connector, flexibility to bend and roll up, resistance to blockages, and long maintenance-free periods reduce overall costs by 40%-60%.

5. Good Environmental Performance: Rubber seepage pipes can be produced from recycled waste tires and are recyclable multiple times, making them highly economical and environmentally friendly..

1. Agricultural Water-Saving Irrigation: Utilizing underground water transmission pipes in drip and seepage irrigation systems allows for precise control over water distribution and helps to minimize soil salinization, (as nano filtration prevents sand from obstructing the emitters.

2. Groundwater Remediation and Water Source Protection: The infiltration and purification of contaminated sites through groundwater (with nanomaterials adsorbing heavy metals and organic matter), or the filtration of water from water sources..

3. Urban Rainwater Management: Permeable pipes in urban construction can quickly infiltrate rainwater and filter pollutants, thereby alleviating waterlogging..

4. Sewage Treatment and Reuse: The underground infiltration treatment of industrial wastewater and domestic sewage utilizes a nano-coating that absorbs Chemical Oxygen Demand (COD), heavy metals, and other pollutants..