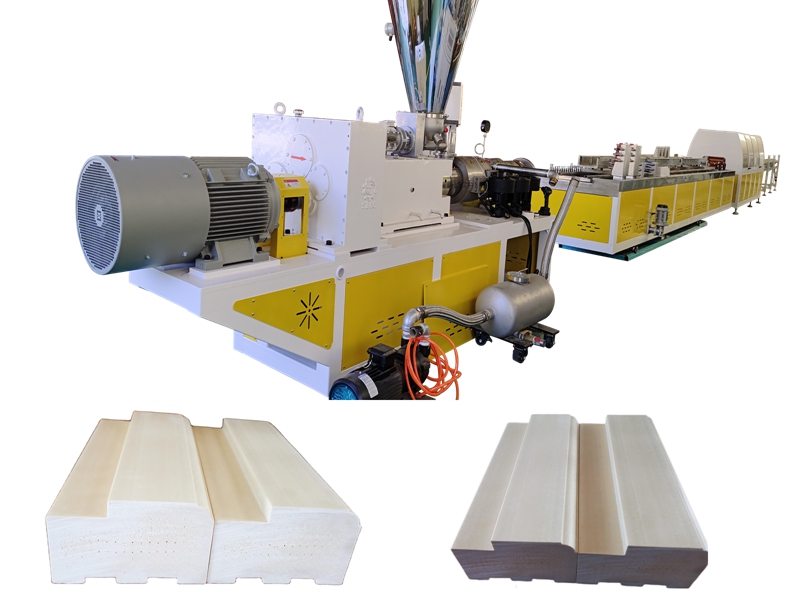

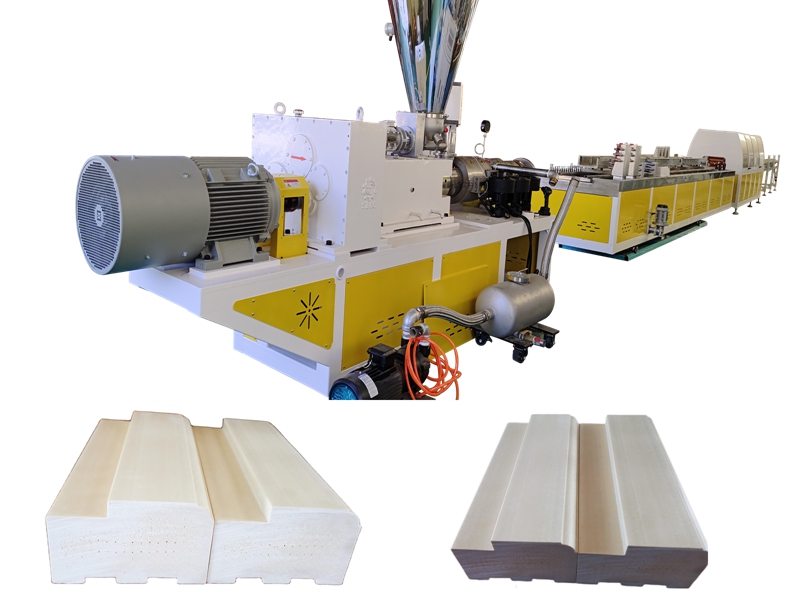

PVC WPC Solid Door Frame Production Extrusion Machine Line with foamed factory price

Yongte PVC WPC Solid Door Frame Production Extrusion Machine Line has many advantages such as high efficiency, high quality, energy saving and environmental protection, easy operation, flexible adaptability, low maintenance cost, safety and reliability, continuous innovation and professional services. it is an ideal choice for WPC profile manufacturers.

features of Yongte Machine Line

-

Efficient extrusion system: using advanced twin-screw extruder, the screw and barrel are specially designed and processed, with good wear resistance and corrosion resistance, and can ensure long-term stable operation. It can fully mix and plasticize wood powder and plastic raw materials, improve production efficiency and product quality, and ensure the extrusion speed and stability of wood-plastic door frame blanks.

-

Precise temperature control system: equipped with a high-precision temperature control system, which can accurately control the temperature of key parts such as extruders and molds. Through multiple temperature sensors and controllers, the temperature of each heating area is monitored and adjusted in real time to ensure that the material is plasticized and extruded under the best temperature conditions, which helps to improve the dimensional accuracy and surface quality of the product and reduce product defects caused by temperature fluctuations.

-

High degree of automation: From raw material mixing, feeding, extrusion, shaping, traction to cutting and other production links, all production links can be automatically controlled. Using advanced PLC control system, the operator only needs to set the relevant parameters on the operation interface, and the equipment can automatically run according to the preset program, reducing the error and labor intensity of manual operation, improving production efficiency and product quality stability, and realizing automatic fault diagnosis and alarm functions, which is convenient for maintenance personnel to troubleshoot in time.

-

Well-designed mold: The mold of Yongte WPC door frame extrusion line is made of high-quality steel, which has high hardness and precision after precision processing and heat treatment. The mold structure is reasonably designed and the flow channel is smooth, which can make the material extrude evenly, ensuring the uniform wall thickness and high dimensional accuracy of the door frame. At the same time, the mold replacement is convenient and fast, and molds of different specifications and styles can be quickly replaced according to customer needs to meet diversified production needs.

Product advantages made by Yongte Machine Line

-

Excellent environmental performance: The produced WPC door frame uses natural wood fiber and recyclable plastic as the main raw materials, does not contain harmful substances such as formaldehyde, benzene, etc., and meets environmental protection standards. In the production process, it will not produce a large amount of wastewater, waste gas and waste residue, which is environmentally friendly and is a green and environmentally friendly building material.

-

Stable and reliable performance: It has good physical and chemical properties, such as waterproof, moisture-proof, insect-proof, corrosion-resistant, and strong weather resistance. It can effectively resist the erosion of the external environment, extend the service life of the door frame, and is not prone to deformation, cracking, fading and other problems. It can adapt to different use environments, such as humid bathrooms, kitchens, and outdoor places.

-

Beautiful and natural appearance: By adjusting the formula and production process, the wood-plastic door frame can have the texture and grain of natural wood, achieving a realistic effect. At the same time, surface treatment can be carried out according to customer needs, such as lamination, spraying, thermal transfer, etc., to achieve customization of various colors and patterns to meet the needs of different decoration styles.

-

Convenient processing and installation: The wood-plastic door frame has similar processing properties to wood, and can be cut, drilled, nailed, bonded and other processing operations, which is convenient for construction personnel to install and debug. Compared with traditional wooden door frames, it is faster and more efficient to install, which can effectively shorten the construction period and reduce labor costs.

Technical parameters

-

Extruder model: According to different production needs, Yongte wood-plastic door frame extrusion line can be equipped with a variety of twin-screw extruders, such as SJZ51/105, SJZ65/132, etc. These extruders have different parameters such as screw diameter and aspect ratio, and the corresponding production capacity and applicable raw materials are also different.

-

Production speed: Generally, the production speed of Yongte WPC door frame extrusion line can reach about 1-5 meters per minute. The specific speed depends on factors such as product specifications, raw material formula and equipment configuration. Higher production speed can meet the needs of large-scale production and improve production efficiency.

-

Product specifications: WPC door frames of various specifications can be produced, and the width, thickness, length and other dimensions of the door frames can be customized according to customer requirements. Common door frame widths are generally between 80-120 mm, thicknesses are between 30-50 mm, and lengths can be cut according to actual use requirements, up to about 6 meters.

Detailed pictures

WPC door profile extrusion line consists of material feeder, conical twin-screw extruder, vacuum calibration table, haul off machine, cutting machine and related auxiliary equipment. The extruder components adopt a unique screw design to avoid high shear and over-plasticization of the raw materials.

The WPC door profile high speed extruder adopts high effective conical double screw extrusion system, it equip with auto feeder, high effective driving system, high speed and high wearing screw, infrated heating system. the main motor power is 45KW equip with ABB inverter control.

High speed cooling and calibration machine: made of stainless steel, including stainless steel frame and sound insulation film with noise reduction. The proprietary stainless steel frame as the water circulation system keeps the internal pipe system, and the unique design structure and reasonable layout can prevent the shaking during the production process and ensure the quality of the product

1, length of table: 11.8meter

2, cooling method: water and vacuum

3, vacuum pump: 7 sets, body made by 304 stainless steel

4, water pump: 1 set, all connected elbows are made by stainless steel

Tractor and cutter machine

It consists of two mechanical units assembled on the same robust frame and has an optional film covering device. The lower traction track is a fixed structure, and the upper traction track is mounted on a high-precision guide plate, and the appropriate pressure can be adjusted. The transmission system of the upper and lower tracks is equipped with two maintenance-free AC frequency conversion motors, which are directly connected with the reducer. Special and quickly replaceable crawler press block. Cutting saw is equipped with maintenance-free horizontal moving cutting device, profile cutting saw synchronized with traction speed, using one-way bearing and chain control, saw blade using pneumatic control; cutting length is controlled by high-precision encoder, and equipped with a high-power chip suction device

The product stacker 3000mm long; consists of a square tube frame and stainless steel flip table with signal from the cutting length counter. The flip table can be adjusted to the height of the extrusion centerline.

Electricity control system

1. Language: English or customized

2. The main electrical control components are Siemens or Schneider products.

3. The main motor is 37-45kw Servo motor

4. The feeder speed regulating device is ABB frequency converter.

5. Omron intelligent temperature control instrument

6. Electrical control cabinet control includes: temperature control system; drive system, pull off system, cooling system.

7. Heating is controlled by a temperature controller, solid-state contactor, and high-temperature resistant wires.

Hot Tags: PVC WPC Solid Door Frame Production Extrusion Machine Line, China, Manufacturer, Supplier, Factory, Buy, Quality, CE, Price