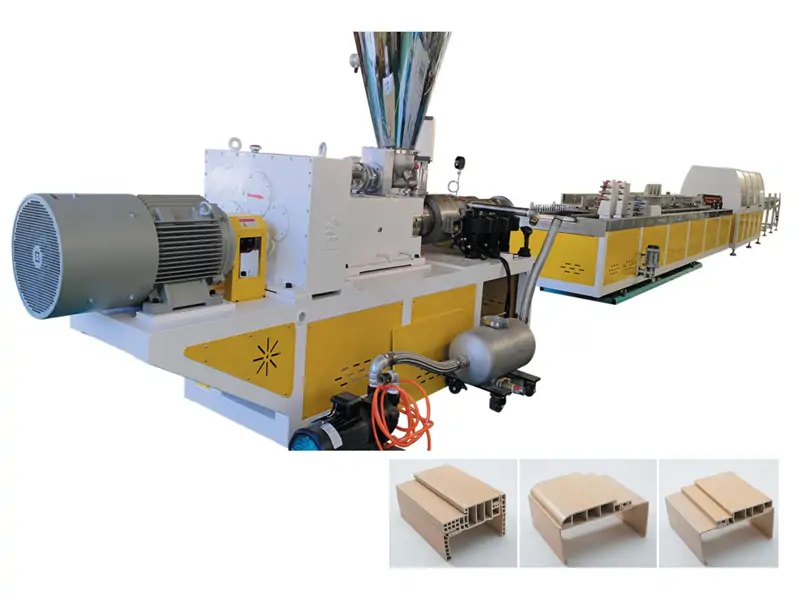

How to Choose the Right WPC Door Frame Machine?

Selecting a suitable WPC (wood-plastic composite) door frame machine is critical for optimizing production efficiency, ensuring product quality, and controlling operational costs—especially for manufacturers aiming to scale their WPC door frame business or enter this market segment.

1. Match the Machine to Your Production Capacity Requirements

The first and most crucial step is to align the machine's output with your actual production scale.

· For small-scale workshops:such as startups or those producing small batches, choose a single WPC door frame machine with semi-automatic production line. These machines have lower upfront costs, occupy less space, and are easy to operate. They are ideal for daily output of 2000-3000 kgs of door frame profiles.

· Medium-to-large factories, (which are engaged in mass production), We can equip high-automatic WPC door frame production line with Double-screw extruders which offer stronger plasticization, high extrusion speed, and stable output. They are equipped with automatic feeding, online cutting, and stacking systems, which reduce labor costs and improve production consistency. 3 sets of SJSZ65/132 WPC door frame extrusion line is suggested for making a capacity of 6000-8000kgs/day

· Key parameters to check include the machine's rated output, extrusion speed, and 24-hour continuous operation stability—avoid overestimating or underestimating capacity to prevent resource waste or production bottlenecks. Ensure compatibility with your raw material type. WPC door frames are made from different raw material formulations, and the machine must be compatible with your specific materials.

· Material categories to consider include:

- PVC-based WPC: Has better rigidity and weather resistance; needs an extruder with enhanced plasticization performance (e.g., barrier-type screws) to avoid material decomposition.

- Foamed WPC: For lightweight door frames; requires a dedicated foaming extrusion system and precise temperature control modules to ensure uniform foam density.

2, Focus on these core components:

-

- Screw and barrel: Select wear-resistant alloy steel materials (e.g., 38CrMoAlA) for longer service life. Double-screw designs are preferred for better material mixing and extrusion stability compared to single-screw ones.

-

- Vacuum calibration table: A must-have component for ensuring profile dimensional accuracy. Choose a machine with a multi-zone vacuum system and adjustable cooling water flow—this prevents profile deformation during shaping.

-

- Cutting system: Automatic CNC cutting machines are more accurate (error ≤ 0.5mm) than manual cutting, and they can be integrated with the production line for continuous operation.

-

- Control system: Prioritize PLC-controlled machines with touchscreen operation. This allows for easy parameter setting (temperature, speed, etc.), real-time production monitoring, and fault alarm functions—reducing the need for skilled operators.

3, Verify certification and quality standards. Certification is a prerequisite for entering target markets:

-

Mandatory certifications: we include CE certification (for EU markets), which ensures compliance with safety, health, and environmental protection standards.

-

Quality inspection: You can check the machine's welding quality, paint finish, and component brands (e.g., famous brands for motors, bearings, and sensors). Reliable components reduce maintenance frequency and downtime.

-

Running inspection: Before the machine delivery, we shall do testing running for the whole production line to ensure the good running condition with stably production and high quality output.

4, Assess after-sales service and technical support.

WPC door frame machines are industrial equipment with long service lives, so after-sales support is as important as the machine itself:

-

Pre-sales service: We can adjust the machine design to produce special-shaped door frame profiles according to your design drawings. We shall help you to make the design of door frames as per your market needs.

-

On-site service: We will send technicians to your factory for installation, commissioning, and operator training, This is particularly important for overseas buyers.

-

Spare parts supply: We will provide lifetime service support with long-term spare parts supply (e.g., screws, heating elements) at reasonable prices, and has a fast delivery channel for international shipments.

-

Maintenance guidance: We will offer online technical support or maintenance manuals to help you troubleshoot common problems quickly.

5, Compare cost-effectiveness, not just price.

Avoid choosing a machine solely based on low price—focus on total cost of ownership (TCO):

-

Initial investment: Balance the machine price with configuration levels (e.g., semi-automatic vs. fully automatic).

-

Operating costs: Consider energy consumption, labor costs, and maintenance costs. A slightly more expensive fully automatic machine may save more money in the long run due to higher efficiency and lower labor requirements.

-

Return on investment (ROI): Calculate based on the machine’s output, product yield, and market demand. A machine that produces high-quality profiles can help you gain more premium orders.