How to solve the deformation problem of wood plastic WPC wall panel in the production process?

The deformation issues in Wood-Plastic Composite (WPC) wall panel production typically originate from multiple factors including material ratios, manufacturing processes, equipment parameters, cooling and molding stages, as well as post-processing. Common deformation manifestations include warping, warping, uneven shrinkage, and surface irregularities, which require comprehensive optimization across the entire production process.

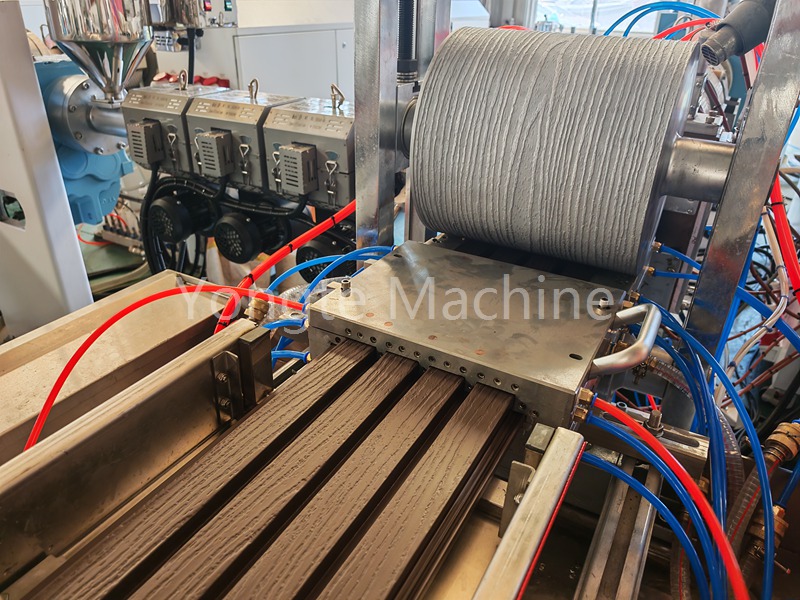

Below are specific cause analyses and systematic solutions developed by Yongte's team through years of practical experience:

Core reasons: Key factors from "raw material" to "finished product"

Wood-plastic composite wall panels are primarily composed of wood fibers (such as wood flour and bamboo powder) and thermoplastic polymers (including PVC, PE, and PP). These two components exhibit distinct characteristics: wood fibers demonstrate strong moisture absorption properties, while plastics show significant thermal expansion and contraction. If production processes fail to balance their performance characteristics, internal stress accumulation may occur, ultimately leading to structural deformation. The specific causes can be broken down as follows:

l Raw material link: high moisture content of wood powder, poor compatibility between plastic and wood powder, unreasonable proportion of additives;

l Plasticizing extrusion process: uneven plasticizing of material, improper screw rotation speed/temperature control, mold design defects;

l Cooling and setting process: cooling speed is too fast/uneven, insufficient bonding of the setting mold;

l Traction cutting link: traction speed and extrusion speed do not match, stress is not released during cutting;

l finishing treatment process: improper stacking of finished products, lack of time limit treatment, loss of temperature and humidity control in storage environment.

Solution: Precision optimization of each link

1, Raw material pretreatment: reduce deformation risk from the source

Raw material is the basis, and two core problems of "wood powder moisture absorption" and "uneven plasticization" need to be solved.

1.1 Strict control of wood flour moisture content

The high moisture content of wood powder (usually required to be less than 3%) will produce bubbles due to water evaporation in the extrusion process, and the finished product is easy to absorb moisture and expand in the later stage, resulting in local deformation.

Solution: The wood powder is pretreated by using hot air dryer (temperature 80-120℃, time 2-4 hours) or vacuum dryer, and stored in a sealed manner immediately after drying to avoid secondary moisture absorption; the moisture content of the raw material is sampled and tested before mixing, and the raw material that fails to meet the requirements is prohibited from use.

1.2 Optimize the ratio of raw materials and improve compatibility

Wood fiber and plastic are not compatible in nature. If no compatibilizer is added, it is easy to lead to poor interfacial bonding between the two, and large difference in shrinkage rate during cooling, resulting in warping.

Rx :

Additives: PVC-based wood-plastic add chlorinated polyethylene (CPE) and acrylic ester; PE/PP-based wood-plastic add maleic anhydride grafted polyethylene (PE-g-MAH), usually 2%-5% of the total raw material, to enhance the bonding force between wood powder and plastic.

Control the proportion of wood powder: too high proportion of wood powder (usually recommended to be less than 60%) will reduce the toughness of materials and easy to crack and deform; it is recommended to adjust according to the use, 40%-50% of wood powder ratio is suitable for home decoration wall panels, and 55% can be appropriately increased for industrial installation.

Add anti-deformation additives: add 1%-3% inorganic fillers such as talc powder and calcium carbonate (which need to be activated by coupling agent) to reduce the overall shrinkage of the material; add 0.5%-1% antioxidant (such as 1010) and uv absorber to reduce the deformation in the later aging.

1.3 Control of raw material mixing uniformity

Mixing unevenness will lead to the imbalance of local wood flour/plastic ratio, and the contraction of each part after extrusion is not consistent.

Solution: Use a high-speed mixer (rotating speed 800-1200r/min), first add plastic particles, compatibilizer and additives, heat to plastic softening (PVC about 100-120℃, PE about 120-140℃), then add dried wood powder, mix for 5-8 minutes, ensure the material is uniform and loose state, no lump.

2, Extrusion molding process: balance of plasticization and stress

Extrusion is the core process of wood-plastic wall panel formation, and uneven plasticization and temperature/rotation speed control are the main causes of deformation.

2.1 Optimization of screw combination and speed

Screw is the key to material plasticization. If the shear force is insufficient, the wood powder and plastic can not be fully integrated; if the shear force is too large, it is easy to cause local overheating and degradation, resulting in internal stress.

Rx :

Screw selection: barrier type screw or separation type screw is used to enhance the shear and mixing capacity of materials, especially for formulations with high wood powder content, the screw length-to-diameter ratio should be increased (L/D=28-32:1 is recommended).

Rotary speed control: Adjusted according to raw material formulation, typically ranging from 30-60 rpm. Excessive rotation speed (>60 rpm) may lead to insufficient plasticization and residual unmelted particles in the material. Conversely, excessively low rotation speed (<30 rpm) results in low production efficiency and prolonged residence time of materials in the barrel, which can cause aging and degradation.

2.2 Precise control of barrel and nozzle temperature

Excessive temperatures may cause plastic degradation and carbonization of wood flour, reducing material strength. Conversely, insufficient temperatures lead to inadequate plasticization and poor material flow, resulting in uneven shrinkage deformation after extrusion. A segmented temperature control system should be implemented, with the die gate temperature slightly higher than the homogenization zone to prevent premature cooling at the die gate, which could cause material discharge issues or surface roughness (increasing deformation risks in later stages). Temperature profiles should be adjusted according to the plastic substrate:

|

Cylinder section |

temperature range (℃) |

act on |

|

Feed section |

140-160 |

Preheat the material to avoid bridging |

|

Compressed section |

160-175 |

Gradually plasticizing, expelling air |

|

Harmonization segment |

175-185 |

Mix thoroughly to ensure uniform plasticization |

|

Head/mouth |

180-190 |

Stable discharge to avoid rapid cooling of materials |

2.3 Optimize mold design and precision

The mold is the direct determinant of the shape of the wall plate. Uneven flow channel of the mold opening and poor adhesion of the molding will lead to uneven force during extrusion of materials and deformation after cooling.

Rx :

Mold mouth flow channel: the gradual flow channel design is adopted to ensure uniform flow rate of material in the mold mouth (avoid fast flow rate at the edge and slow flow rate in the middle), and the surface of the flow channel should be polished (roughness Ra ≤ 0.8μm) to reduce the flow resistance of material.

Shaping mold: design the vacuum adsorption shaping mold according to the thickness of the wall plate (the thickness of the wall plate is 5-10mm, and the vacuum degree is controlled at 0.04-0.06MPa), ensure that the wall plate is closely attached to the shaping mold, and open uniform cooling water channels in the shaping mold to avoid local cooling dead corners.

2.4 Cooling and setting: the key to eliminate internal stress

Cooling and improper setting is the most direct cause of wall panel bending and warping, the core is "uniform cooling, slow release of stress".

2.4.1 Use of "gradual cooling" instead of "sudden cooling"

The temperature of the freshly extruded wall plate is high (about 160-180℃). If it is directly put into the low-temperature cooling tank (<20℃), the surface will shrink and harden quickly, while the interior is still in a high-temperature softening state. In the later stage, the internal contraction will pull the surface, resulting in warping (usually "concave in the middle and up on both sides").

Solution: Set up a three-stage cooling system:

First-level cooling (stabilizing mold cooling): the wall temperature is reduced from 180℃ to 80-100℃ through the water channel in the stabilizing mold (the water temperature is controlled at 50-60℃), and the shape is preliminarily fixed;

Secondary cooling (spray cooling): use atomizing spray equipment to evenly spray 40-50℃ warm water, and reduce the temperature to 40-50℃;

Level 3 cooling (cold water cooling): Enter the cold water tank at 20-30℃ and cool completely to room temperature (stay time 5-8 minutes).

Key: the cooling water should cover both sides of the wall plate evenly to avoid excessive cooling on one side (guide plates can be set in the water tank to ensure smooth flow).

2.4.2 Control cooling speed and time

Cooling speed should match the wall thickness: thin wall thickness <5mm, the total cooling time can be controlled in 8-10 minutes; thick wall thickness> 8mm, it needs to be extended to 12-15 minutes to ensure complete internal cooling and avoid "secondary shrinkage" in the later stage.

(4) Traction and cutting: avoid deformation caused by external forces

The imbalance of traction speed and improper cutting time will artificially increase the internal stress of wall panels, resulting in deformation.

2.5 Matching of traction speed and extrusion speed

Too fast traction speed: will stretch the wall plate, resulting in an increase in longitudinal shrinkage rate, later easy to "shrink" deformation;

Too slow traction speed: the wall plate stays in the molding for too long time, which is easy to sag and bend due to its own weight.

Solution: Utilize variable frequency speed-regulated traction machines. Through real-time sensor monitoring of extrusion output, maintain the traction-to-extrusion speed ratio between 1.05-1.1:1 (ensuring the traction speed slightly exceeds the extrusion speed to guarantee flat wall panels without wrinkles). Simultaneously, maintain uniform pressure across both upper and lower rollers (pressure 0.2-0.3MPa) to prevent uneven loading on any single side.

2.5 Cutting time and equipment precision

When the wall panel is not completely cooled (temperature> 30℃) during cutting, or the cutting saw blade is not sharp and the rotation speed is too low, the unbalanced force at the cutting edge will cause local deformation.

Rx :

Cutting time: after the third level of cooling, ensure that the wall temperature is reduced to room temperature (<25℃) before cutting;

Cutting equipment: high-speed circular saw (revolutions 3000-4000r/min) is used. The saw blade needs to be polished regularly. During cutting, the wall plate is fixed through the guide device to avoid shaking during cutting.

2.6 Post-treatment and storage: consolidate the molding effect

Even if the production process is well controlled, improper post-processing can still lead to deformation, and "stress release" and "environmental control" should be focused on.

2.6.1 Finished product time treatment (stress release)

The newly produced wall panels still have uncompleted internal stress, which is easy to gradually deform if directly stacked.

Solution: The cut wall panels are neatly stacked on a flat pallet, and the height of each pile is not more than 1.2 meters (to avoid deformation of the bottom caused by heavy pressure). The wall panels are placed in a normal temperature (20-25℃) and ventilated environment for 7-10 days to let the internal stress be naturally released. This process is called "time effect treatment".

2.6.2 Standardized storage and transportation

Storage environment is humid: wood powder absorbs moisture and expands, resulting in wall board bending;

Tremendous change of ambient temperature: plastic thermal expansion and cold contraction intensifies, causing warping.

Rx :

Storage warehouse: keep dry (relative humidity ≤60%), ventilated, avoid direct sunlight and near heat source (such as heating, boiler);

Stacking method: The wall panels should be stacked "face to face, back to back" in an alternating manner, separated by wooden strips (spaced 50-100mm) in the middle to ensure air circulation; the bottom should be raised with cushion wood (at least 10cm above the ground) to prevent moisture from invading the ground;

Transportation process: cover with rainproof cloth to avoid rain; handle carefully during loading and unloading to avoid compression and collision.

sum up

The deformation challenge of wood-plastic composite WPC wall panels represents a "systemic process" that requires adherence to a comprehensive workflow: moisture control in raw materials → uniform plasticization → gradual cooling → stress release → standardized storage. The key lies in balancing the distinct characteristics of wood fibers and plastics to minimize internal stress accumulation. By precisely regulating critical parameters (particularly moisture content, temperature, and cooling rates) alongside optimized equipment and quality monitoring, deformation can be controlled within 1%, meeting both production requirements and application needs.