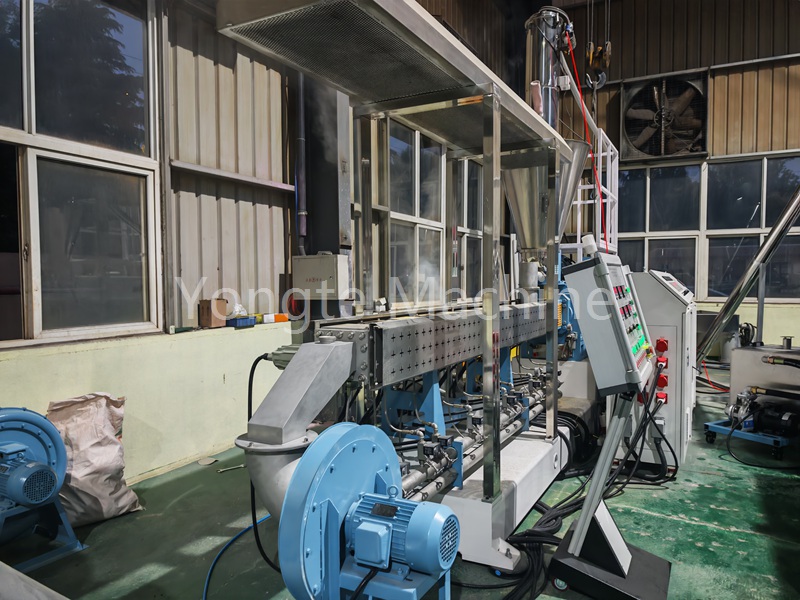

Yongte has successfully completed high-efficiency WPC granulation machine

🎉Great news! After a month of meticulous manufacturing, Yongte has successfully completed the full production process of its new high-efficiency WPC granulation machine! This equipment is specifically customized for processing wood powder-plastic mixed raw materials, achieving breakthroughs in both raw material compatibility and production efficiency.

① Capacity Upgrade: The optimized screw structure is designed for common formulations such as PP/PE-based wood-plastic blends and bamboo powder-plastic composites, increasing production capacity by over 30% compared to traditional models, reaching up to 600kg/hour (depending on raw material moisture content and ratio adjustment).

② Quality Assurance: Through a precise temperature control system and a two-stage pelletizing process, the produced wood plastic pellets are uniform, effectively avoiding problems such as breakage, bubbles, and surface irregularities during downstream extrusion of wood plastic products, helping customers improve the yield of finished products.

③ Low Carbon and Energy Efficiency: Equipped with an ultra-high-efficiency servo motor, it consumes 15% less energy than the industry average, reducing carbon emissions and operating costs for businesses. From initial consultation with the customer and polishing of customized drawings, to precision machining of core components (critical parts undergo quenching treatment, doubling wear resistance), to 72 hours of continuous no-load testing and three trials with different raw materials—every step reflects Yongte's R&D experience and stringent quality control standards. To address the challenges of wood-plastic materials, which are susceptible to moisture and sticking to the wall, the equipment is equipped with an automatic material removal device and a drying and pre-mixing hopper interface to further reduce manual operation. This "craftsmanship" not only demonstrates our technological strength but also deeply addresses our customers' production needs!

We look forward to collaborating with more partners in the wood-plastic processing industry. Whether building new production lines or upgrading and replacing old equipment, we offer a one-stop service package: equipment customization + free installation guidance + a one-year warranty + lifetime technical consulting. We unlock new production efficiencies with cost-effective equipment and jointly expand the scope of the wood-plastic circular economy!