Yongte Plastic Machinery has significantly upgraded its screws, helping companies reduce costs and increase efficiency without increasing prices.

If you're struggling with uneven mixing, waste, and rapid equipment wear in your wood-plastic composite (WPC) production, Yongte Plastic Machinery's latest developments may be worth your attention. We understand that as a WPC manufacturer, you daily balance quality and cost. While upgrading equipment is appealing, the accompanying price pressure can often be daunting. Based on this insight, Yongte Plastic Machinery has completed a core upgrade of its entire line of co-extrusion equipment, maintaining the same price point, hoping to provide you with a truly cost-effective option.

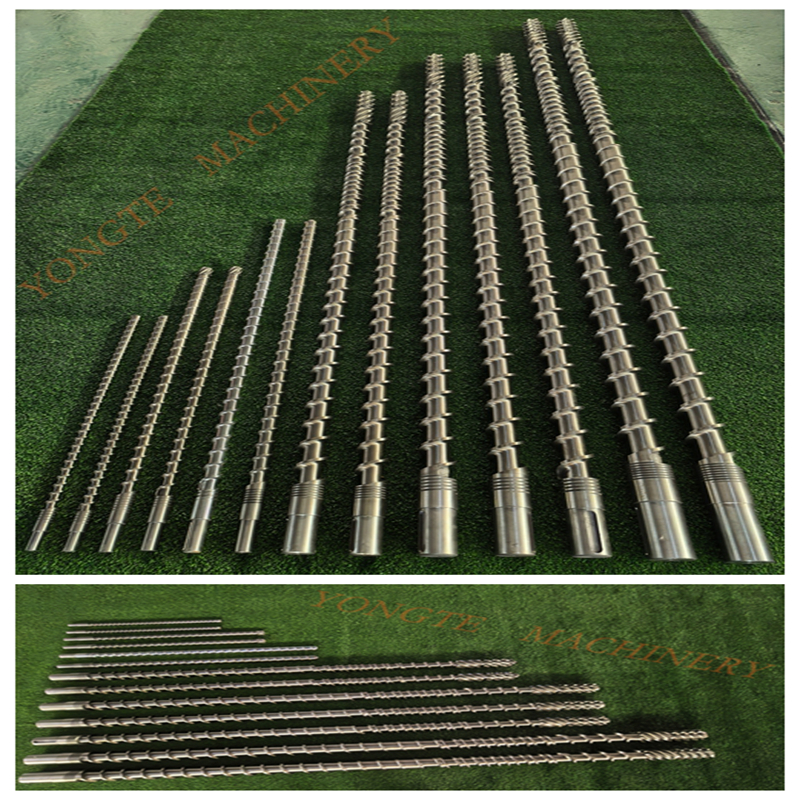

The core of this upgrade focuses on the key component, the screw. We've implemented substantial improvements to address practical challenges such as wood powder agglomeration and excessive wear. The new screw utilizes a 38CrMoAlA alloy steel base and undergoes a nitriding treatment. High-end models also feature a tungsten carbide/nickel-based alloy dual coating, increasing wear resistance by over 50%, making it more resistant to long-term wear from wood powder and fiber. We also optimized the structural design of the feed, compression, and homogenization sections, focusing on addressing white specks and fiber clumps, ensuring a more uniform blend of wood powder and plastic. Extremely high processing precision and mirror-smooth finish reduce material retention and leakage, ensuring more stable pressure and temperature during extrusion, and ensuring reliable, long-term continuous production.

For us, technological upgrades aren't the goal; helping our customers succeed is paramount. We've calculated that the upgraded equipment will deliver tangible benefits: enhanced screw conveying and self-cleaning capabilities effectively reduce downtime. Customers report that average daily production time has increased from 18 to 21 hours, increasing production capacity by nearly 17%. Improved mixing has reduced scrap from 8% to below 3%. Based on a daily raw material consumption of 1.2 tons (8,000 yuan/ton), this translates to a monthly raw material cost savings of over 10,000 yuan. The new screw's lifespan has been extended to 2-3 years, reducing replacement frequency and costs. Furthermore, power consumption has been reduced by 10%-15%, saving nearly 20,000 yuan annually on a 100kW production line.

"I wanted to upgrade before, but I was worried about the cost. Unexpectedly, Yongte simply switched to a high-end screw without raising the price. We ran a trial batch of outdoor flooring, and the surface finish is indeed much better, and the customer feedback is even more positive." – This is the actual feedback from a trial customer.

Our ability to "upgrade without price increases" isn't due to some mysterious technology, but rather to our ability to absorb these costs ourselves through supply chain optimization, in-house development of core components, and improved production processes. We believe that only by ensuring our customers have access to high-quality equipment without burden can the entire industry move forward.

Currently, over a dozen companies like you have chosen upgraded Yongte equipment, with applications spanning outdoor flooring, decorative panels, and logistics pallets. If you're interested in improving product quality and reducing overall production costs, please feel free to contact us for more details about the upgrade or to schedule a trial run. Yongte Plastic Machinery looks forward to being your reliable partner.