MPP Electric Power Pipe Production Line for China customer

Recently, our company has completed 2 sets of MPP electric power pipe production line customized for domestic customers, which are used to produce MPP (modified polypropylene) power cable protection pipes. Now the equipment has been stably producing high-quality MPP power pipes in the customer's factory.

Yongte MPP electric power pipe equipment has the following advantages:

Highly automated: The advanced control system can realize the automated operation of the entire production process from raw material transportation, extrusion, shaping, traction to cutting, reduce manual intervention, and improve production efficiency and product quality stability.

High production efficiency: The extruder equipped with an efficient screw and a rapid cooling and shaping system can achieve high-speed extrusion and rapid shaping, thereby increasing the production speed of pipes and increasing output. At the same time, the various components of the equipment are closely matched, stable in operation, and can be continuously produced for a long time.

Energy saving: The production line uses a permanent magnet servo motor, which can accurately control the speed; it adopts an energy-saving and efficient automatic heating and temperature control system to reduce energy waste; the production line can effectively reduce 10-15% of power consumption.

Good pipe quality: Through the professionally designed screw structure and mold, the plasticization quality of the pipe can be good, the inner and outer walls are smooth, the dimensional accuracy is high, and the roundness is good. In addition, the equipment also has a complete cooling and shaping system, which helps to improve the physical properties and appearance quality of the pipe, making it have strong corrosion resistance, impact resistance, aging resistance and good electrical insulation performance.

Strong flexibility: According to different production needs, production parameters can be adjusted to produce MPP power pipes of various specifications and lengths to meet the use requirements of different projects. For example, by changing the mold and adjusting the process parameters, pipes with diameters ranging from tens of millimeters to hundreds of millimeters and different wall thicknesses can be produced.

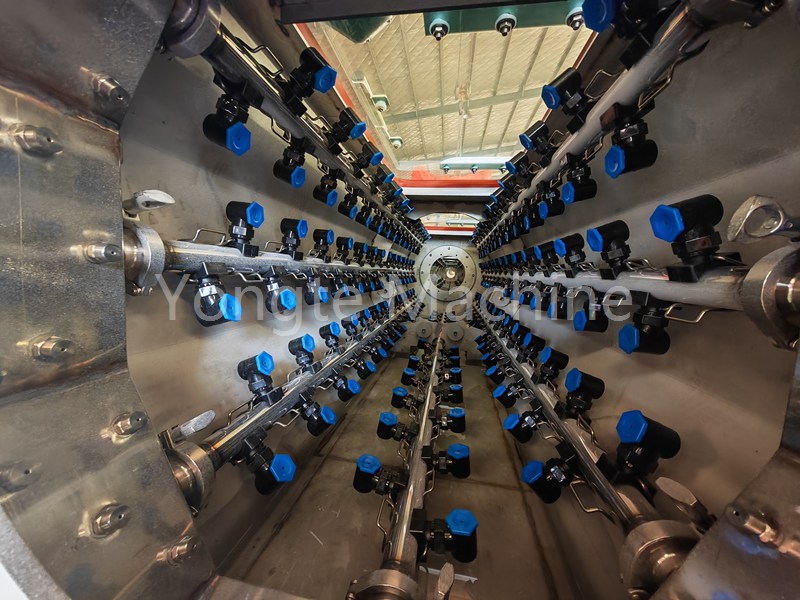

Pictures of Yongte MPP power pipe production line