Yongte is PPR Pipe Extrusion Line professional manufacturer based in China, our machine has advantages of high automation, high effiency, high quality, easy operation, power saving and easy maintenance.

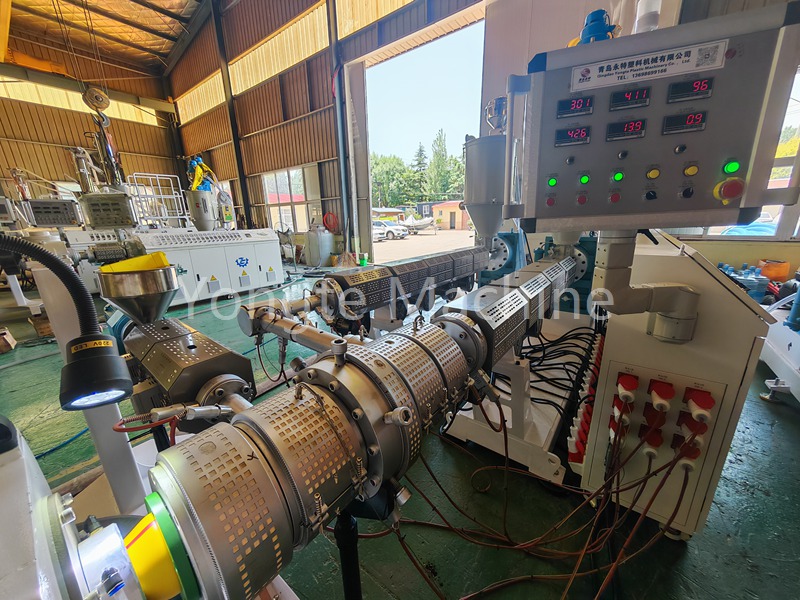

Yongte is PPR Pipe Extrusion Line professional manufacturer based in China, specializes in high-performance, heavy-duty core equipment for modern plastic pipe manufacturing. The PPR pipe production line consists of several core systems, each playing a critical role in the manufacturing process: raw material processing, extrusion, mold, cooling and sizing, traction, cutting, and electrical control. The raw material processing system ensures consistent quality by pretreating PPR materials through drying and mixing. The extrusion system uses multiple extruders to heat, melt, and extrude specific raw material types. The mold system is essential for co-extrusion, with its runner design determining the three-layer composite effect and pipe cross-sectional shape. The cooling and sizing system rapidly shapes pipe blanks using sizing sleeves and cooling tanks, guaranteeing dimensional accuracy and surface quality. The traction system draws pipes from the mold at a steady speed to control wall thickness and length. The cutting system slices pipes to precise lengths. Finally, the electrical control system fine-tunes temperature, pressure, speed, and other parameters to maintain stable operation across the entire line. Our machine has advantages of high automation, high effiency, high quality, easy operation, power saving and easy maintenance.

The core of Yongte’s PPR Pipe Extrusion Line lies in its synchronized co-extrusion process: multiple extruders simultaneously melt and plasticize PPR raw materials tailored for the inner, middle, and outer layers—each formulated to meet distinct functional requirements. These customized molten materials are then fed into a precision-engineered co-extrusion mold, where they are uniformly compounded to form a seamless three-layer pipe blank. The blank undergoes a streamlined post-processing workflow, including precision sizing, rapid cooling, constant-speed traction, and automated fixed-length cutting, to produce final PPR pipes with consistent quality and precise dimensional accuracy.

1. Raw Material Processing System: Handles pretreatment (drying, mixing, homogenization) of diverse PPR raw materials to eliminate moisture and ensure uniform material consistency—laying the foundation for defect-free pipe production.

2. Extrusion System: The system for multi layer PPR pipe production comprises three extruders, along with their feeding and control systems. One extruder is for the middle layer of PPR plastic pipes, the second for the inner and outer layers, and the third for the pipe's marking line.

3. Electrical Control System: Equip with ABB inverter, Innovance servo motor, Omron temperature controller, Siemens contractors and other high quality electric parts, the control system precisely regulates temperature, pressure, extrusion speed, and traction rate across the entire line. This real-time monitoring and adjustment ensures 24/7 stable operation and minimizes production downtime.

4. PPR Pipe Mold: The custom-designed die head features precision-engineered flow channels that dictate the bonding quality of the three-layer structure and the exact cross-sectional shape of the pipe. Its tailored design guarantees tight layer adhesion and uniform thickness distribution across the pipe wall.

5. Vacuum calibration and Cooling System: Combines a vacuum sizing sleeve and high-efficiency cooling water tank to rapidly cool and shape the pipe blank. This step locks in dimensional accuracy (±0.1mm tolerance) and delivers a smooth, blemish-free surface finish.

5. Meter Counting Encoder: This device works in tandem with the cutting machine to achieve automatic fixed-length cutting of pipes.

6. Traction Machine: We configure caterpillar units according to pipe diameter (e.g., double-caterpillar, triple-caterpillar, four-caterpillar, and fixed-caterpillar types).Pulls the formed pipe from the mold at a constant speed to precisely control wall thickness and overall length—critical for meeting strict industry size standards.

7. Automatic Cutting Machine: Equipped with touch screen programmable control, this dust-free and chip-free cutting machine ensures clean and precise cuts.Automatically cuts pipes to preset lengths (adjustable via touchscreen) with clean, burr-free edges, eliminating post-processing needs.

7. High-Quality PPR Pipes (End Products): Pipes produced by this machine feature smooth inner/outer walls, uniform thickness, and excellent mechanical performance.

In practical production, Yongte’s PPR Pipe Extrusion Line fully leverages the advantages of advanced co-extrusion technology. Our R&D team customizes raw material formulations for each extruder based on specific market demands, while precisely controlling temperature, pressure, and extrusion speed to ensure seamless compounding of three-layer PPR materials within the mold. Factory testing confirms that the produced pipes not only deliver exceptional physical properties but also achieve industry-leading standards in surface finish and dimensional precision. The mature application of three-layer PPR pipe co-extrusion technology in our production lines serves as a valuable benchmark for peers in the industry.

PPR pipes, produced by Yongte's PPR pipe extrusion line, are known for their exquisite appearance and high brand recognition, aiding our clients in enhancing product competitiveness and expanding market share. With the advantages of being environmentally friendly, durable, non-toxic, and odorless, as well as possessing high-temperature resistance, corrosion resistance, excellent thermal insulation properties, and ease of installation, PPR pipes are increasingly replacing traditional galvanized and copper pipes in global water supply, drainage, heating, and industrial fluid transportation fields.