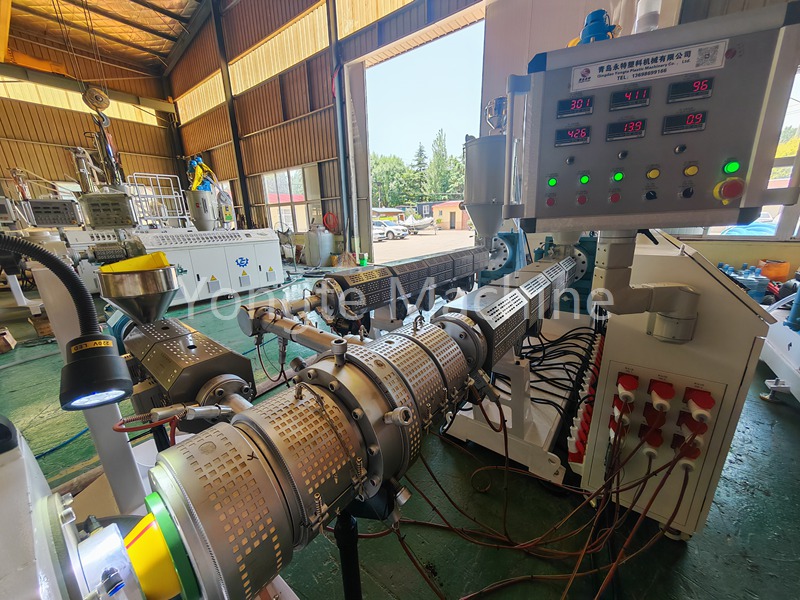

Yongte is professional manufacturer factory for producing 16-63mm Three layer PPR hot water pipe extrusion machine,it is specially designed for making multi layer of PPR hot water pipe by co-extrusion technology,PPR hot water pipe extrusion machine is mainly composed of material loader, extruders, die and mold, cooling and calibration tank, pull off tractor, cutting device, and control system, etc.

The PPR hot water pipe extrusion machine is used for the production of PPR (Polypropylene Random) hot water pipe. PPR is a new type of polymer material, because of its excellent heat resistance, pressure resistance, environmental protection and convenient installation characteristics, is widely used in building water supply and drainage, HVAC, rural drinking water safety and other fields. the 16-63mm three layer PPR hot water pipe extrusion machine is specially designed for making multi layer of PPR pipe by co-extrusion technology, the PPR pipe structure can be ABA or AB or even ABC.

PPR hot water pipe extrusion machine is mainly composed of material loader, extruders, die and mold, cooling and calibration tank, pull off tractor, cutting device, and control system, etc. The extruder is the core production machine of the extrusion machine, which is responsible for heating the PPR particles to a molten state and extrusion them through the mold; The cooling and calibration device is responsible for cooling and setting the squeezed PPR pipe in a short time to ensure its dimensional accuracy and physical properties. laser printer machine can be equipped online to printing words(such as pipe size, manufacturer information) on the PPR pipe.

Item

Equipment

1

SJ65/30 single screw extruder

2

SJ50/30 single screw co-extruder

for the middle layer of PPR pipe

3

4

Die and molds

5

SJ25 single screw extruder

for identification marking line

6

cooling and calibration tank

7

Caterpillar hauling off machine

double caterpillar strong force

8

Cutting machine

automatic cutter without dust

9

Automatic Product stacker

6 meter length

10

Electricity control system

equip with ABB inverter, Omron temperature controller, Siemens PLC control, Siemens contractors

Note

for the inner and outer layer of PPR pipe

Auto material loader

with drying function

special designed for three layer PPR pipe making

6 meter length, fast cooling design with both water and vacuum cooling.

1. Raw material preparation: mix the PPR granules in a certain proportion and send them into the hopper of the extruder. the hopper should equip with drying function to take out the moisture in the PPR material.

2. Heating and extrusion PPR pipe material: The extruder heats the PPR particles to a molten state and forms them through the mold to form the PPR pipe. for making three layer PPR pipe, it will need two extruders; and also need the third extruder for making the color marking line.

3. Cooling and calibration: the extruded PPR pipe enters the cooling and calibration device and cools quickly under the action of cooling water. both water cooling and vacuum forming are necessary to make good PPR pipe product.

4. Cutting and conveying: the finalized PPR pipe is cut into a certain length through the cutting device and sent to the next process through the conveying device.

5. Inspection of packaging: the quality inspection of PPR pipe, the packaging after qualified, and finally become the finished product on the market.

1. Strong and durable, high quality: our wood-plastic production machine is made of high quality materials, durable, can withstand a variety of bad weather and use environment test, to ensure a long time of stable operation.

2. Unique design, excellence: our product design fully considers the user's use experience, every detail has been carefully polished, aiming to bring users the ultimate use experience.

3. Environmental protection, energy saving, green production: wood-plastic production machine in the production process can effectively reduce energy consumption and waste production, in line with the green production concept of modern society.

4. Efficient production and increased production capacity: Our wood-plastic production machine has an efficient production capacity, which can quickly complete a large number of production tasks, help users to increase production capacity, and win more business opportunities.

5. Simple operation, convenient maintenance: our product operation interface is simple and clear, easy to use, and at the same time, it is also very convenient to maintain, which greatly reduces the operating cost of users.

6. Intimate service, the whole worry: we provide a full range of pre-sale, sale and after-sales service, to ensure that users in the use of timely and professional support and help.

7. High cost performance, excellent value for price: our wood-plastic production machine ensures high quality, the price is also very reasonable, so that users really feel the shopping experience of excellent value for price.

8. Intelligent control, easy management: the product is equipped with intelligent control system, users can easily manage the production process through mobile phones or computers, to achieve intelligent production.