Multi Layer HDPE PPR Plastic Pipe Coextrusion Machine is to use multiple extruders to melt and plasticize PPR raw materials with different formulas at the same time, and then use specially designed molds to compound these different melts together to form a tube blank with a three-layer structure, and then go through subsequent sizing, cooling, traction, cutting and other processes to finally obtain the finished pipe.

Yongte Multi Layer HDPE PPR Plastic Pipe Coextrusion Machine with CE certificate

The HDPE PPR multi-layer plastic pipe co-extrusion production line is the core equipment in the field of modern plastic pipe manufacturing. It uses advanced co-extrusion technology to accurately integrate three layers of PPR materials with different functions or characteristics to produce pipe products with better performance and richer functions.

Working principle and structural composition

The core principle of Multi Layer HDPE PPR Plastic Pipe Coextrusion Machine is to use multiple extruders to melt and plasticize PPR raw materials with different formulas at the same time, and then use specially designed molds to compound these different melts together to form a tube blank with a three-layer structure, and then go through subsequent sizing, cooling, traction, cutting and other processes to finally obtain the finished pipe.

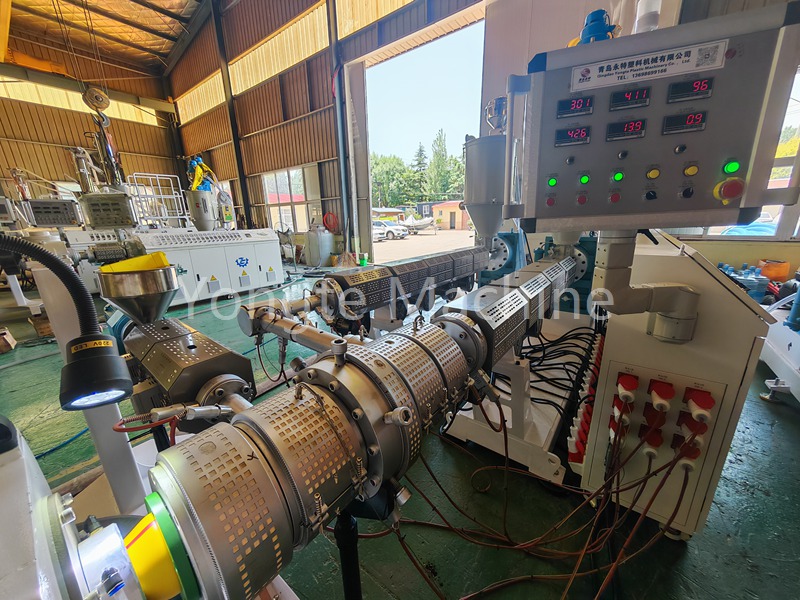

From a structural point of view, it is mainly composed of raw material processing system, extrusion system, mold system, cooling and shaping system, traction system, cutting system and electrical control system. The raw material processing system is responsible for drying, mixing and other pretreatment of different types of PPR raw materials to ensure the stability of raw material quality; the extrusion system includes multiple extruders, each of which is responsible for heating, melting and extruding a raw material; the mold system is the key to co-extrusion, and its flow channel design determines the composite effect of the three-layer structure and the cross-sectional shape of the pipe; the cooling and shaping system uses the sizing sleeve and cooling water tank to quickly cool and shape the pipe blank to ensure the dimensional accuracy and surface quality of the pipe; the traction system pulls the pipe out of the mold at a constant speed to control the wall thickness and length of the pipe; the cutting system cuts the pipe according to the set length; the electrical control system accurately controls the temperature, pressure, speed and other parameters of the entire production line to ensure the stable operation of the production line.

Detailed Pictures of Yongte Machine

1, Extrusion system: the extrusion system includes three extruders and its feeding system and control system, one extruder is for the middle layer of HDPE PPR plastic pipe, second extruder is for inner and outer layer of the plastic pipe, third extruder is for the marking line of the pipe.

2, Co-extrusion die head, mold and sizers: special designed die head for co-extrusion material flow according to required thickness for each layer.

3, Cooling system: it includes vacuum sizing cooling tank (8 meter length) and spraying water cooling tank (8 meter length). high effective cooling system can increase the production speed.

4, meter counting encoder device can work together with the cutting machine to achieve automatic fixed length cutting.

5, Pull off tractor machine,we will equip quantity of caterpillars according to the pipe diameter, such as double caterpillar type, three caterpillar type, four caterpillar type and fix caterpillar type

6, Automatic cutter machine: programed with touch screen control, non-dust and non-chip cutting machine,

Advantage of Yongte Machine

Take Yongte's 75-125mm three-layer PPR pipe production line as an example. In actual production, this production line fully utilizes the advantages of co-extrusion technology. Yongte Company carefully designs the raw material formulas of different extruders according to market demand, and makes the three-layer PPR material perfectly compounded in the mold by precisely controlling the temperature, pressure and extrusion speed of each extruder. After the test machine inspection, the produced pipes not only have excellent physical properties, but also have reached the industry-leading level in appearance and dimensional accuracy. The successful acceptance of this production line marks Yongte Company's mature application of three-layer PPR pipe co-extrusion production technology, and also provides other companies with experience for reference.

Production advantages of three-layer PPR pipe

Compared with traditional PPR pipe production lines, three-layer PPR pipe co-extrusion production lines have significant advantages. In terms of performance improvement, by co-extruding PPR materials with different properties, such as using antibacterial PPR raw materials in the inner layer of the pipe, high-strength PPR materials in the middle layer, and adding anti-ultraviolet additives to the outer layer, the pipe can have multiple properties such as antibacterial, high strength, and aging resistance to meet the needs of different usage scenarios. In terms of cost control, although the initial investment of the co-extrusion production line is relatively high, in the long run, because it can produce high-value-added pipe products, and through reasonable raw material ratios and process control during the production process, it can reduce raw material waste and improve production efficiency, thereby effectively reducing unit product costs. In addition, the pipes produced by this production line have exquisite appearance and high brand recognition, which helps companies improve product competitiveness and market share.

With the continuous improvement of pipe performance requirements in the construction, water supply and drainage and other industries, the three-layer PPR pipe co-extrusion production line will play an increasingly important role in the field of plastic pipe manufacturing with its unique advantages, and promote the industry to develop in a higher quality and more intelligent direction.