Yongte 16-63mm PPR Pipe Extrusion Machine equipped with high effective extrusion machine, high speed cooling system, automatic cutter, high quality and automatic eletric control system. it has advantages of high speed production, high automatic, easy operation, and low power consumption

Yongte 16-63mm PPR Pipe Extrusion Machine with CE certificate

Yongte 16-63mm PPR Pipe Extrusion Machine is used for making PPR pipe with mono layer or three layer, the PPR pipe is widely used for hot water supply. It uses advanced extrusion technology, high speed cooling and calibrating system, automatic pull and cutting machine, automatic feeding and discharge system, automatic temperature control system. it has advantages of high production capacity, high speed production, low power consumption, high automatic, easy operation, easy maintainence.

The core principle of 16-63mm PPR Pipe Extrusion Machine is to use multiple extruders to melt and plasticize PPR raw materials, and then use specially designed molds to compound these different melts together to form a tube blank, and then go through subsequent sizing, cooling, traction, cutting and other processes to finally obtain the finished pipe.

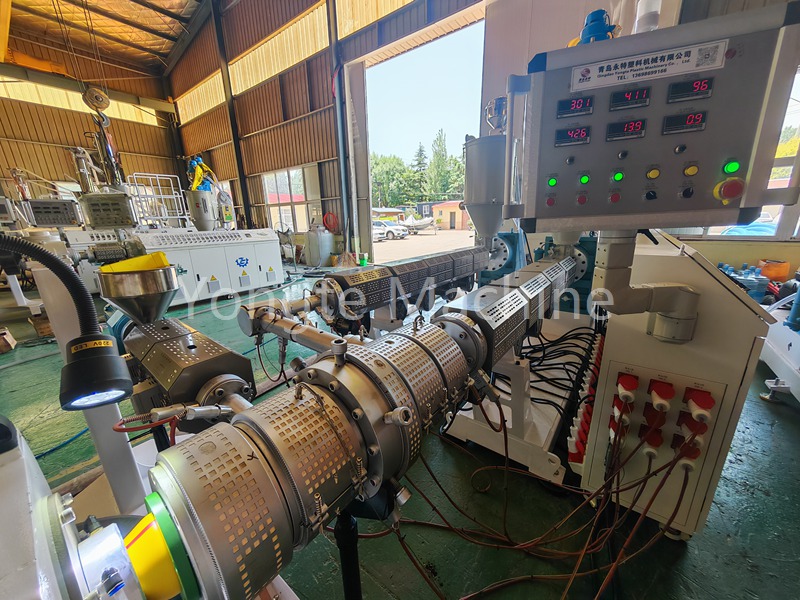

Detailed Pictures of Yongte Machine

1, Extrusion system: the extrusion system includes single screw extruders and its feeding system and control system, for multi-layer PPR pipe production, it will need to equip 3-4 sets of extruders at the same time according to customer's requirements. one extruder is for the middle layer of HDPE PPR plastic pipe, second extruder is for inner and outer layer of the plastic pipe, third extruder is for the marking line of the pipe.

2, PPR pipe die head, mold and sizers: special designed die head for co-extrusion material flow according to required thickness for each layer.

3, PPR pipe calibration and Cooling system: it includes vacuum sizing cooling tank (8 meter length) and spraying water cooling tank (8 meter length). we equip high effective cooling system which can increase the production speed and ensure the pipe shape to be uniform.

4, meter counting encoder device can work together with the cutting machine to achieve automatic fixed length cutting.

5, Pull off tractor machine,we will equip quantity of caterpillars according to the pipe diameter, such as double caterpillar type, three caterpillar type, four caterpillar type and fix caterpillar type

6, Automatic cutter machine: programed with touch screen control, non-dust and non-chip cutting machine,

7, PPR pipe discharge stacker: 6m length SS stacker with auto discharge function.

Advantage of Yongte PPR pipe Machine

Take Yongte's 16-63mm three layer PPR pipe production line as an example. In actual production, this production line fully utilizes the advantages of co-extrusion technology. Yongte Company carefully designs the raw material formulas of different extruders according to market demand, and makes the three-layer PPR material perfectly compounded in the mold by precisely controlling the temperature, pressure and extrusion speed of each extruder. After the test machine inspection, the produced pipes not only have excellent physical properties, but also have reached the industry-leading level in appearance and dimensional accuracy. The successful acceptance of this production line marks Yongte Company's mature application of three-layer PPR pipe co-extrusion production technology, and also provides other companies with experience for reference.