Yongte WPC Profile Co-extrusion Machine is a equipment specially used to produce wood-plastic composite wpc products. Wood-plastic composite is a new type of environmentally friendly material that combines the advantages of wood and plastic. It has the texture and beauty of wood and the durability and waterproofness of plastic.

WPC profile co-exrtusion machine is a equipment specially used to produce wood-plastic composite wpc products. Wood-plastic composite is a new type of environmentally friendly material that combines the advantages of wood and plastic. It has the texture and beauty of wood and the durability and waterproofness of plastic.

Yongte is professional manufacturer for complete WPC production machine with high quality and great service. we supply the turnkey production line for turnkey project from A to Z, including plastic wastage recycling machine, wood powder making machine, WPC mixing machine, WPC granulation machine, WPC decking extrusion line, embossing machine, sanding machine, brushing machine and other auxiliary equipment.

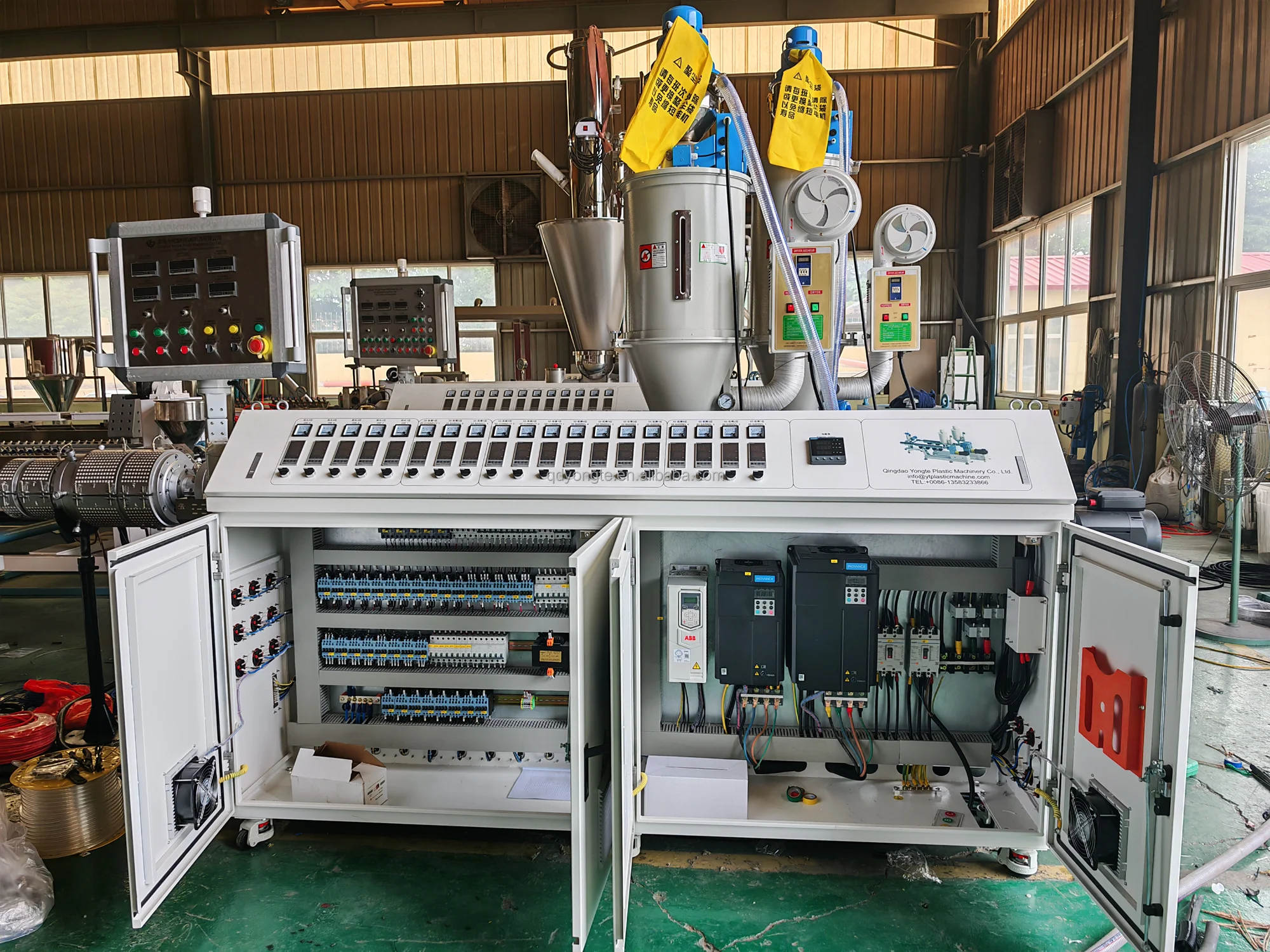

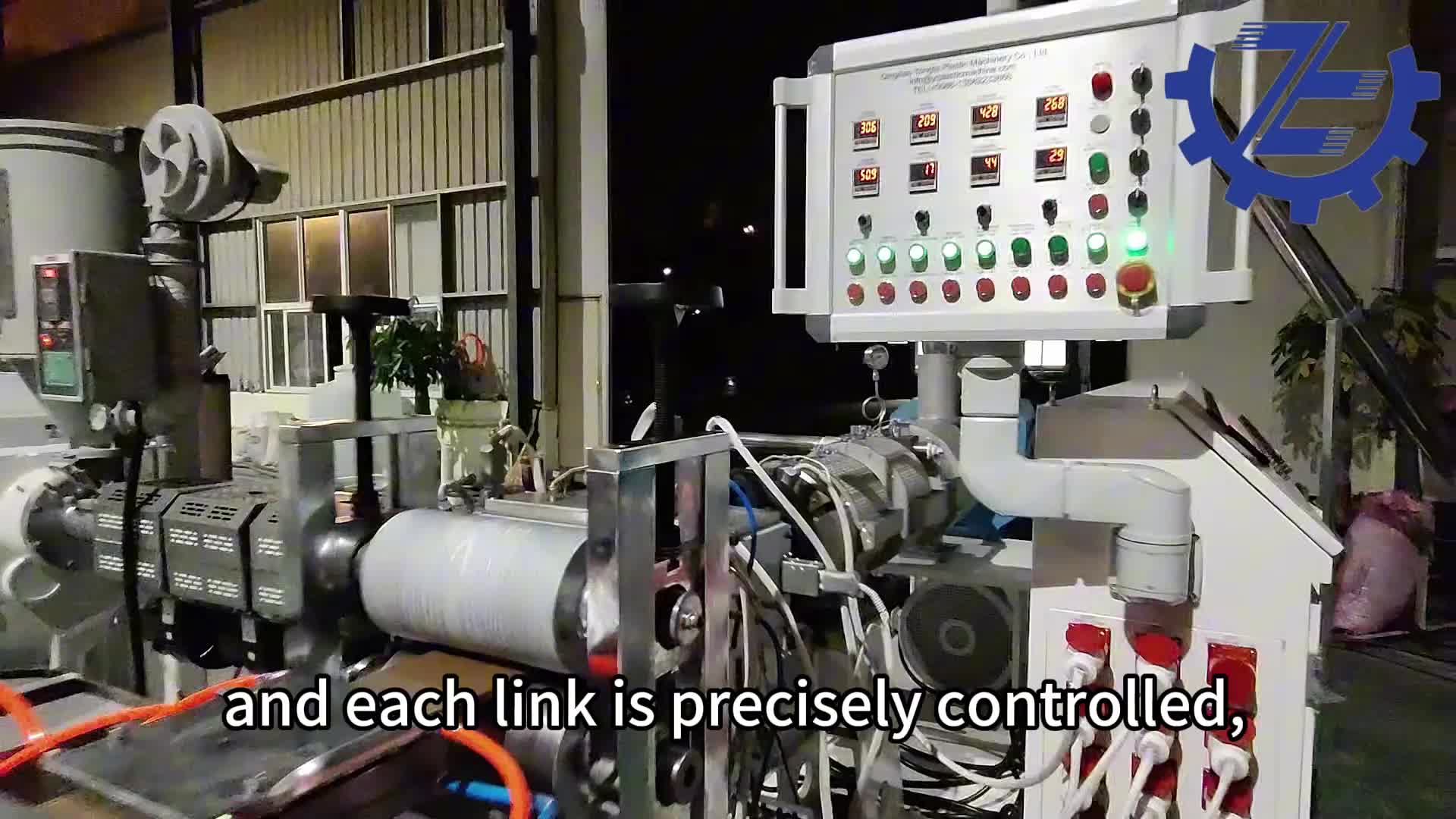

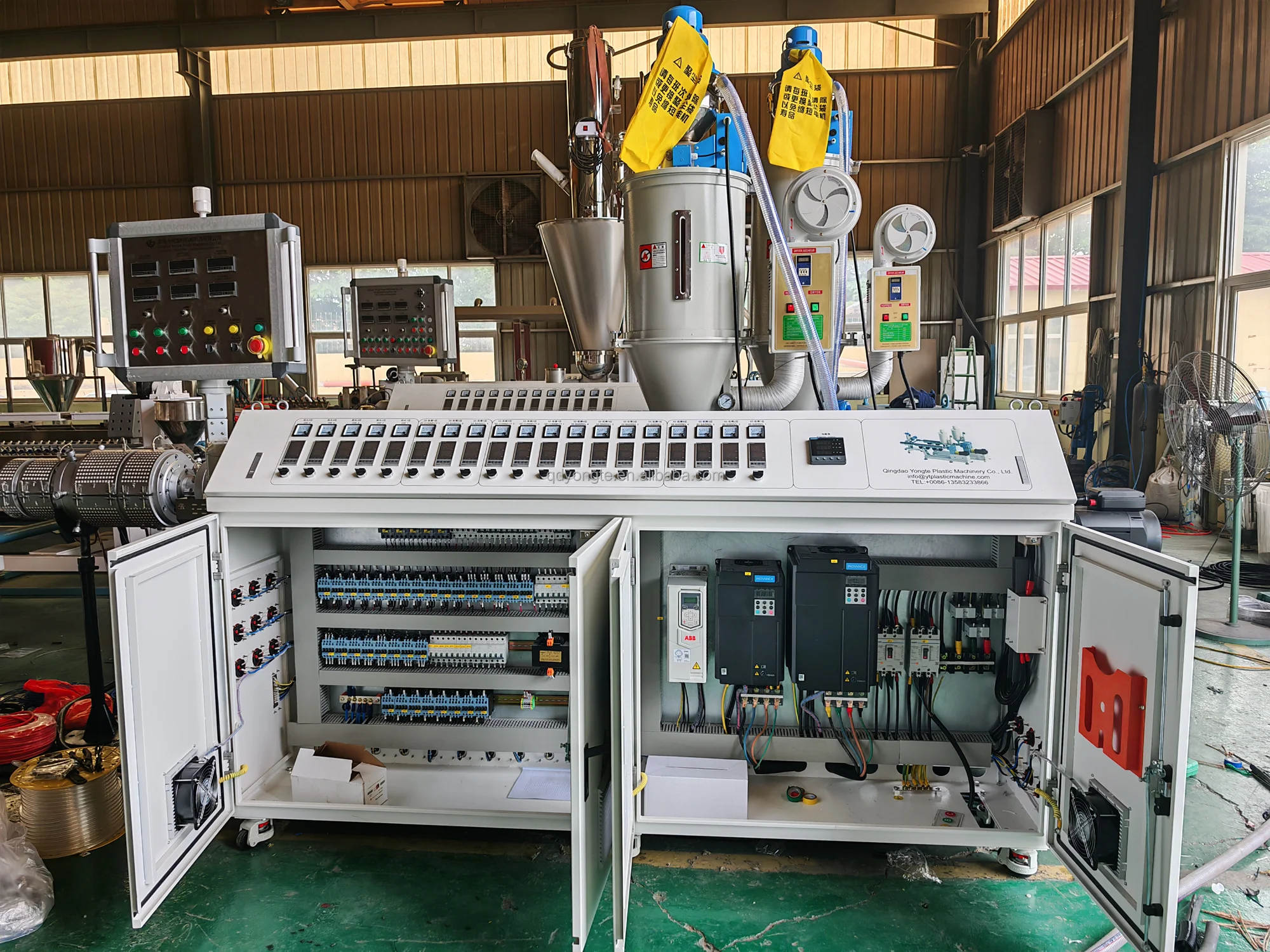

WPC decking extrusion machine is composed by auto feeder, conical double screw extruder, die and mold, cooling and calibration machine, tractor and cutter, and electric control system. WPC granules are feeded into the hopper of the extruder. The extruder plasticizes the mixture through high temperature and pressure, and then extrudes it through a die into a profile of the desired shape. Finally, after cooling and cutting, the finished wood plastic profile is obtained. Co-extrusion is optional for making better wpc products with anti-weather layer.

Equipment List

|

Item

|

Equipment

|

Function

|

|

1

|

Auto feeder

|

it is used for feeding material to the extruder automatically

|

|

2

|

65/132 conical double screw extruder

|

it is used for melting the material and plastiziation

|

|

|

co-extruder machine

|

it is used for co-extrusion high quality wearable layer on the WPC decking surface to make ABA design

|

|

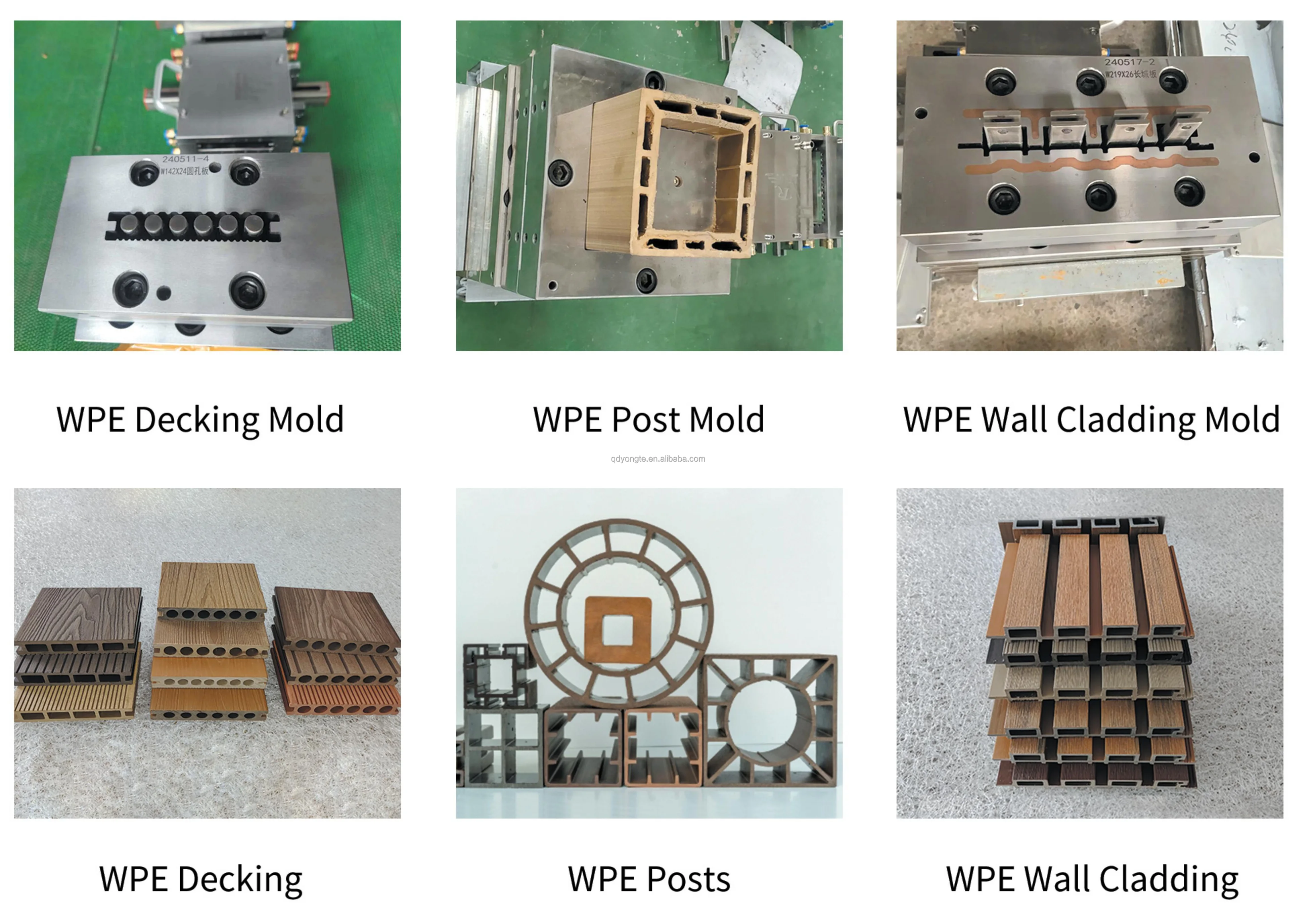

3

|

die and mold

|

it will decide the size and shape of the product

|

|

4

|

online embossing machine

|

it is used for embossing wooden grain design on the WPC decking surface

|

|

5

|

calibration and cooling machine

|

it is used for cooling the WPC decking product to ensure the product size and shape without deformation.

|

|

6

|

Haul off and cutting machine

|

it is used for pull the WPC products forward and automatic cut the wpc products into required length

|

|

7

|

Dust collector

|

It is used for collecting the cutting dust to ensure non-pollution to environment

|

|

8

|

Product stacker

|

it is used for collecting the WPC products

|

|

9

|

Electricity control system

|

it is the control system for the complete production line, including temperature control, speed control and other electric part control

|

|

Name

|

Screw Feeder machine

|

|

Material

|

304 stainless steel

|

|

Motor

|

2.2kw

|

|

Screw

|

120mm diameter

|

|

mode

|

Automatic feeding

|

|

Name

|

65/132 Conical twin screw extruder

|

|

Screw diameter

|

65mm

|

|

Main motor

|

37KW

|

|

Heating

|

electric, auto temperature control,

around 20KW

|

|

Vacuum pump

|

4KW

|

|

Capacity

|

150-250 kg/h

|

|

Name

|

Co-extrusion machine

|

|

Screw diameter

|

35mm

|

|

Main motor

|

5.5KW

|

|

Heating

|

auto electric heating

|

|

Capacity

|

15-25 kg/h

|

|

Name

|

Die and mold

|

|

Material

|

3Cr17 mold steel

|

|

Calibrators

|

240mm*2 pcs

|

|

Cooling tank

|

2000mm*2pcs

|

|

Name

|

Online 3D embossing machine

|

|

Roller diameter

|

165-295mm

|

|

Roller heating

|

Electric heating

|

|

Roller cooling

|

water cooling

|

|

Pattern design

|

engraved 3D deep design

|

|

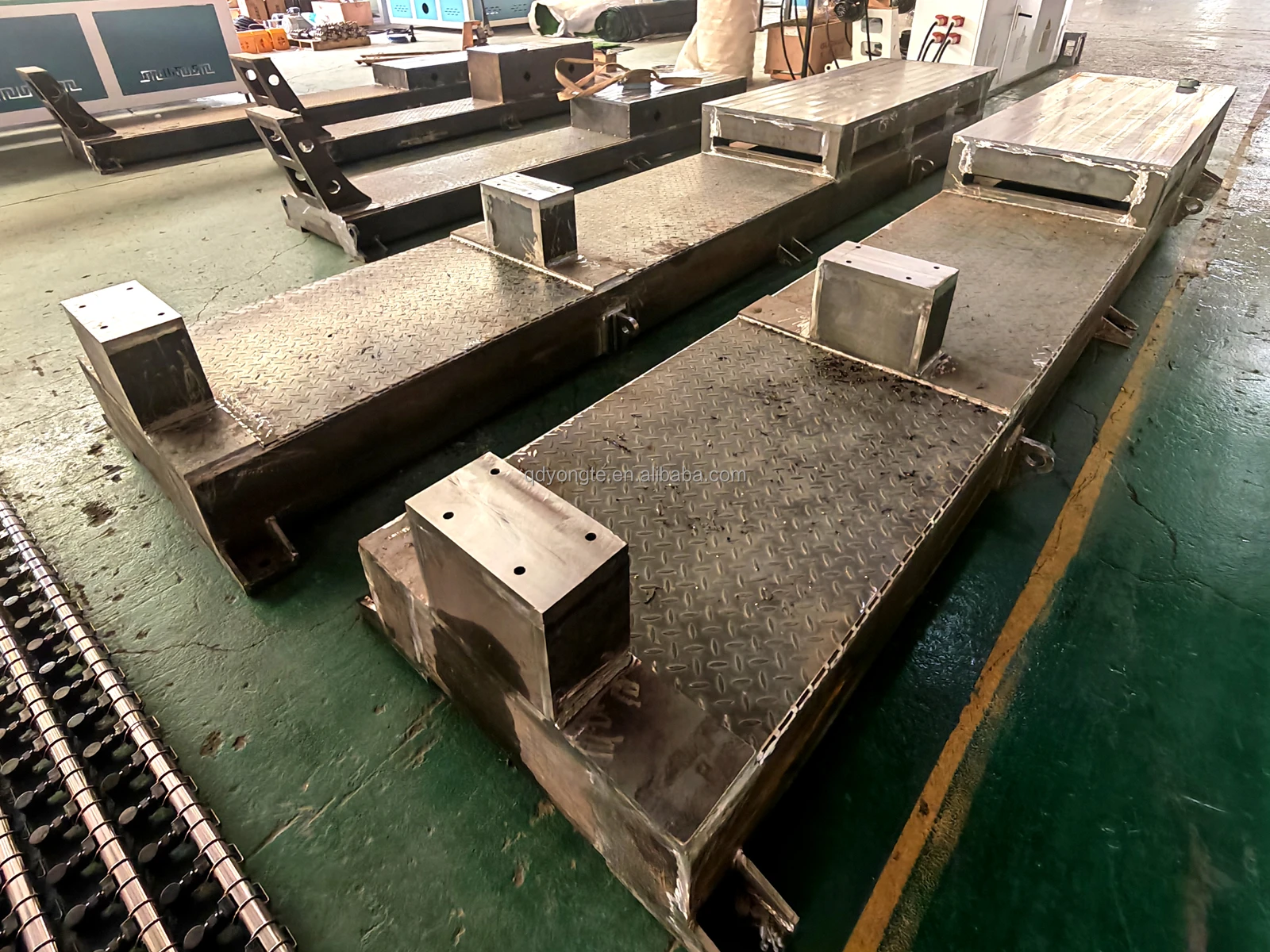

Name

|

Cooling and calibration table

|

|

Length

|

6000mm

|

|

Water pump

|

2.2KW

|

|

Material

|

Surface by 304 stainless steel

|

|

Movement

|

electric drive adjustment

|

|

Name

|

Haul off and cutting machine

|

|

Haul power

|

2.2kw *2pcs

|

|

Cutting power

|

3KW

|

|

Caterpillar

|

Double caterpillar

|

|

Cutting mode

|

Automatic fixed length cutting

|

|

Cutting blade

|

Diamond cutting blade

|

|

Name

|

Dust collector

|

|

Power

|

3KW

|

|

Quantity of bags

|

2 pcs of collection bags

|

|

suction hose

|

flexible reinforced plastic hose

|

|

Name

|

Electricity control cabinet

|

|

Inverter

|

ABB inverter or Innovance servo controller

|

|

Contractors

|

Siemens or Schneider brand

|

|

Temperature controller

|

Omron brand

|

|

PLC control

|

Siemens brand (optional)

|

|

Cabinet

|

Four doors big cabinet with enough volume, with cooling blower

|

Our Advantages