Yongte Plastics Machinery: Making Wood-Plastic Composite (WPC) Car Interior Flooring "Worry-Free"

Today, competition in the new energy vehicle market is no longer limited to batteries and intelligent driving; every gram of weight inside the car has become crucial for automakers to tap into their potential. As a large interior component, car interior flooring is becoming a key area for achieving lightweight and environmentally friendly transformation. Wood-plastic composite (WPC), a material made from wood powder, bamboo powder, and plastic, is gradually becoming a favored green solution in the industry due to its significant weight reduction advantages, low odor characteristics, and recyclability.

Yongte Plastics Machinery, based in Qingdao, has keenly grasped this trend, leveraging over a decade of experience in WPC equipment. While not an industry giant, they have successfully developed and optimized a complete production line specifically for producing automotive-grade WPC flooring, relying on a deep understanding of the technological challenges. Currently, this production line has achieved stable batch supply, effectively helping many component partners overcome the production bottleneck from "being able to do it" to "doing it well."

The market demand for WPC flooring is very clear. On the one hand, increasingly stringent global environmental regulations and consumers' genuine concern about the driving range of electric vehicles combine to create a strong "pull." Compared to traditional metal flooring, wood-plastic composites can effectively reduce component weight, directly contributing to improved driving range; their low volatility also significantly improves in-vehicle air quality, making it easier to meet environmental access standards in domestic and international markets. On the other hand, for automakers, this is also an effective path to enhance the green competitiveness of their products while keeping overall costs under control.However, transforming ideal materials into stable and reliable mass-produced parts is not a smooth process. The biggest technological challenge lies in the fact that natural plant fibers and plastic substrates are like "oil and water," making it difficult to achieve a uniform and stable composite. Early attempts by manufacturers often encountered problems such as insufficient product strength and easy warping and deformation, resulting in low yield rates. Yongte Plastic Machinery addresses these common industry pain points by making a series of targeted improvements to its equipment.

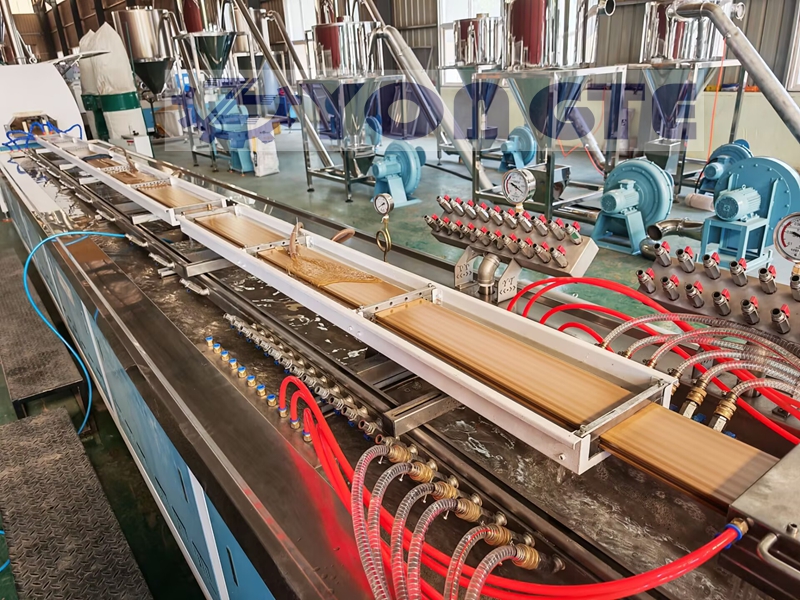

"Our logic in making equipment is simple: to make it worry-free for customers while also allowing them to make money," Yongte's technical director summarized their philosophy. This production line boasts a high degree of automation, from raw material pretreatment and precise compounding to extrusion molding and post-processing, minimizing reliance on manual labor. For example, addressing the hygroscopic nature of wood and bamboo powders, the line integrates a highly efficient drying and fine grinding system to ensure raw material stability and uniformity. A high-precision loss-in-weight feeding system enables precise control of the plastic-to-fiber ratio, guaranteeing the stability of composite material performance from the source.

At the heart of the production line is a specially designed co-rotating parallel twin-screw extruder. Its screws utilize a wear-resistant alloy, capable of withstanding long-term abrasion from wood fibers, reducing customer maintenance costs and downtime risks. A precise temperature control system ensures melt uniformity and stability, thereby reducing the scrap rate to an extremely low level. Furthermore, the line's excellent flexibility has been highly praised by customers, significantly reducing the debugging time for switching molds between different car models, enabling rapid response to automakers' flexible order requirements of "multiple batches, small quantities."

This solution also provides comprehensive considerations regarding environmental protection and sustainability. Dust generated during production is recycled through a closed system, protecting the workshop environment and preventing raw material waste; minimal process waste gas is treated to meet emission standards. More importantly, wood-plastic composite flooring manufactured using this production line has a significantly lower carbon footprint over its entire lifecycle than traditional materials. This adds green value to downstream customers' products, providing a strong competitive advantage for entering high-end markets, especially overseas.

Market recognition has ultimately validated the value of this solution. According to feedback from partner clients, after implementing Yongte's production line, the overall yield of wood-plastic composite flooring has significantly improved, with production capacity increasing by approximately 30%. The products have successfully entered the mainstream passenger vehicle supply chain and achieved exports to overseas markets. Currently, Yongte's series of equipment serves customers in more than twenty provinces across China, and overseas inquiries and orders continue to grow. This Qingdao-based company has established a solid reputation in the niche market of wood-plastic composite equipment.