Why screw of WPC granulator machine break down in running?

Sometimes, Users may encounter situations where the WPC granulator screw suddenly breaks. The main reasons maybe: material performance is not up to standard, improper operation, lack of maintenance and design defects. Targeted investigation is needed to avoid frequent failure.1、Materials and Manufacturing IssuesThis is the basic cause of the fracture of the rebar block, which directly determines the load resistance of the component.

Screw Material mismatch: When threaded blocks are made of ordinary steel (e.g., No.45 steel) instead of specialized wear-resistant alloys (e.g., 38CrMoAlA or bimetallic composites), they may lack sufficient strength and toughness during high-temperature and high-pressure wood-plastic processing, leading to brittle fracture.

Defects of heat treatment process: if the quenching temperature is not proper and the tempering is not sufficient during heat treatment, the internal stress concentration of the material or the imbalance between hardness and toughness (such as high hardness but poor toughness) will be caused, and the fracture will be caused by impact during operation.

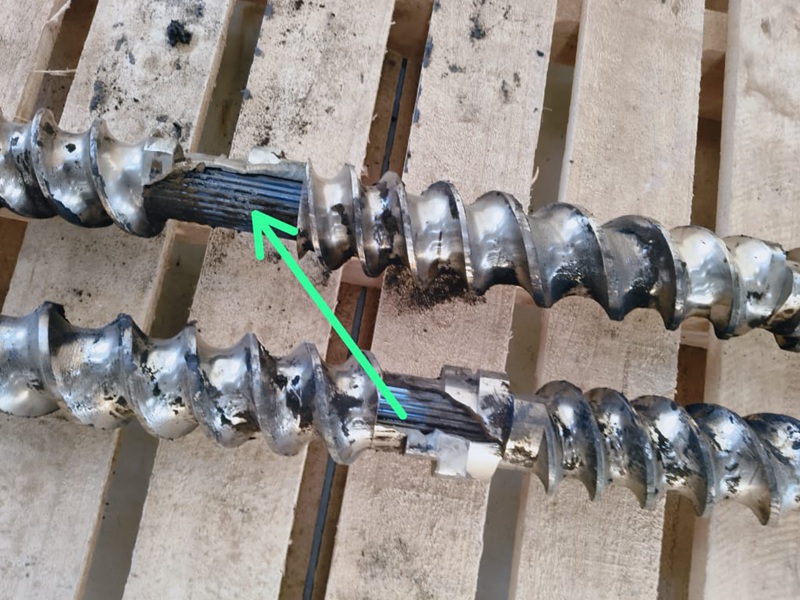

Insufficient machining accuracy: the root of the thread is too small, burrs or cracks exist, which will form stress concentration points, and gradually expand to fracture after long-term operation.2、Improper useNon-standard behavior in daily operation will make the threaded block bear the load beyond the design range.

Unstable feeding: the feeding amount of wood-plastic raw material (such as wood chips and plastic particles mixture) fluctuates, resulting in drastic fluctuations in screw load, and the threaded block alternately bears overload and impact, and fatigue fracture under repeated stress.

Foreign matter in the material: metal blocks, stones and other hard objects are mixed in the raw material, which will be stuck in the thread groove, and the thread block will be subjected to a great torque instantly, resulting in cracking or shear fracture.

Improper startup/shutdown procedures: Failure to preheat or feed at low speed during startup causes excessive stress on the threaded block at low temperatures. Failure to empty the material during shutdown leads to solidification after cooling. Forced startup during subsequent operations may cause the threaded block to fracture due to overload.3、Maintenance is missingLong-term lack of scientific maintenance will accelerate the aging of the rebar block and cause fracture.

Wear and tear: The hard particles in the wood-plastic raw material will continue to wear the thread surface, resulting in shallow thread tooth type, reduced force area, increased local stress, and finally fracture.

Abnormal assembly clearance: after long-term use, the clearance between the threaded block and the screw and barrel becomes larger, and radial jumping occurs during operation. The threaded block is subjected to additional radial force, and it is easy to break from the root.

Insufficient lubrication: if the lubrication fails in the connection between the threaded block and the drive shaft, dry friction will be generated, which will not only increase the running resistance, but also lead to local overheating, reduce the strength of the material and induce fracture.4、Design and matching defectsProblems in the design of the equipment will make the threaded block have the risk of fracture from the beginning of use.

Unreasonable structure design: the thread angle and pitch of the thread block are not matched with the characteristics of wood-plastic raw materials, or the root of the thread is not strengthened (such as not increasing the rounded corner), which is easy to form a stress weak area.

Power and load mismatch: If the selected thread block specification is not matched with the power of the host (such as a small thread block with a high-power motor), the processing is easy to exceed the load limit of the thread block due to overload.

To reduce WPC granulator screw breakage, it is recommended to control the source: prioritize bimetallic thread blocks with strict heat treatment during purchase; ensure uniform feeding and regular cleaning of foreign matter in raw materials during use; inspect thread block wear and assembly clearance every 100-200 hours of operation.