Yongte's WPC Hollow Door Panel Production Line Empowers Furniture Companies to Transform

The current home furnishing market faces challenges, putting pressure on solid wood door manufacturers. Due to its significant advantages, WPC hollow door panels are becoming a new direction for many furniture companies seeking to transform. Yongte Plastic Machinery's WPC hollow door panel production line, with its outstanding performance, is gaining increasing attention within the industry and becoming a key piece of equipment enabling these companies' transformation.Solid wood door panels are prone to mold and deformation in humid environments, such as kitchens and bathrooms, often limiting their service life. In contrast, WPC hollow door panels offer excellent water resistance, maintaining structural stability even in prolonged exposure to humidity, and are less susceptible to mold, warping, or deformation. Regarding environmental friendliness, some solid wood door panels use formaldehyde-containing adhesives during production, which can adversely affect indoor environments. WPC door panels, on the other hand, are primarily made from recycled plastics and agricultural and forestry waste, eliminating the need for glue during production, making them more aligned with modern consumers' pursuit of healthy homes. Solid wood doors require regular waxing and repainting to maintain their appearance and performance; otherwise, they can easily lose their luster or even crack. Wood-plastic door panels, on the other hand, are easy to maintain, typically requiring only a damp cloth to wipe, significantly reducing maintenance costs and effort over long-term use.

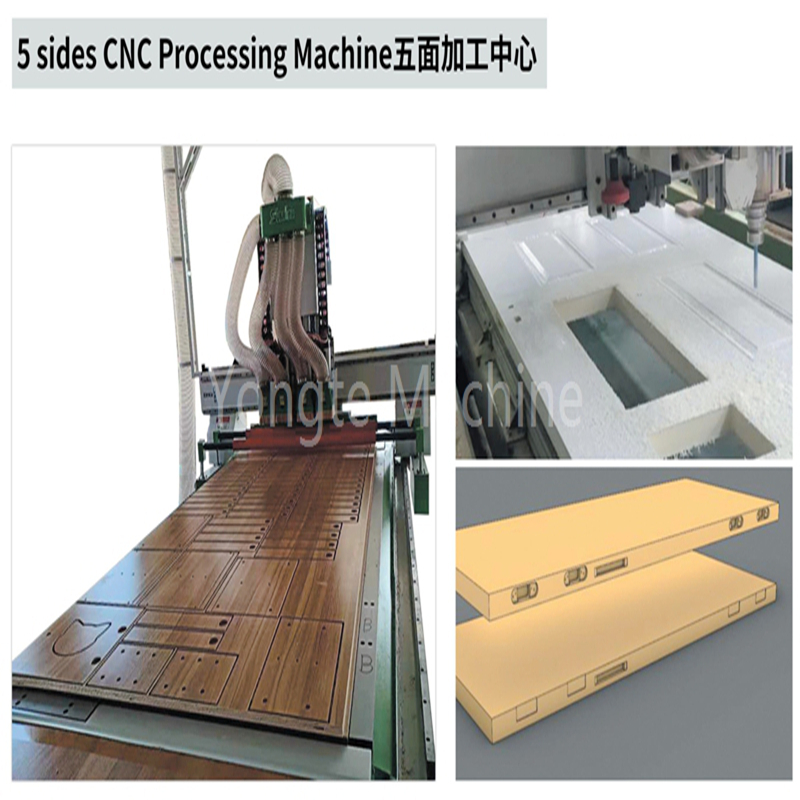

Yongte Plastic Machinery's production line offers significant advantages in efficiently producing these high-quality door panels. Its core lies in its unique "one-step" molding process: No pre-granulation of the raw materials is required. Sawdust, straw powder, and recycled plastic can be directly fed into its proprietary conical twin-screw extruder, mixing and shaping the materials in a single operation. This not only reduces equipment investment in the granulation process but also effectively reduces energy consumption, resulting in sustained cost savings for the company. Furthermore, the significant reduction in raw material costs significantly reduces procurement pressure for the company.Production efficiency and product stability are the highlights of this production line. The vacuum shaping table quickly and accurately shapes the extruded door panels, ensuring dimensional accuracy. The smooth operation of the crawler tractor ensures continuous and smooth production, enabling rapid response to order demands and reducing the risk of inventory overstock. The produced wood-plastic door panels feature a hollow structure, resulting in uniform thickness and stability even in alternating hot and cold environments. Their durability far exceeds that of traditional solid wood door panels.

To meet the market's growing demand for customization, the production line's quick-change mold system provides high flexibility. Changing molds for different wood grains or styles requires only two operators working together in a short period of time, easily meeting the requirements of small, diverse orders. By adjusting parameters, the line can also produce door panels of varying thicknesses and widths, adapting to a wide range of furniture specifications, including cabinets, bathroom cabinets, and wardrobes.From a return on investment perspective, this line offers a relatively short payback period, realizing faster returns than traditional solid wood door production lines. In the current market environment, Yongte Plastic Machinery's wood-plastic hollow door panel production line, through its outstanding performance in cost control and production efficiency, coupled with the core advantages of wood-plastic door panels, provides solid support for the transformation and upgrading of furniture companies, and is expected to drive the industry towards more efficient and sustainable development.