Corn Waste "Alchemy" to Easily Create New Wood-Plastic Materials

After harvesting corn, what happens to the cobs, stalks, and leaves left in the field? In the past, they were often burned or randomly dumped, causing both waste and pollution. Now, Yongte Plastic Machinery's wood-plastic production line can transform this "waste" into valuable materials, directly producing practical and durable wood-plastic products like outdoor flooring, fencing, and flower boxes, truly turning "waste" into gold. Corn is grown worldwide, covering vast swaths of the Americas, Asia, Europe, and Africa, leaving abundant scraps. Harvesting this waste is a low-cost, stable source, practically free raw material, significantly reducing production costs without worrying about running out of food.

The core of this production line is to transform corn waste. Raw material pretreatment is fundamental: the harvested cobs, stalks, and leaves must first be cleaned—dirt, stones, and residual corn kernels—to remove impurities, otherwise the machinery will suffer and the finished product will have a bumpy surface. After cleaning, crush the stalks and cores into a fine powder similar to flour. Crush the leaves to add toughness. Skimp on drying: If the powder is too wet, subsequent processing will result in bubbles, and the finished product will be full of honeycombs, significantly reducing its strength.

Corn flour alone can't support wood plastic; recycled plastic pellets are essential. Pellets made from discarded bottles and old agricultural film are excellent, saving money and being environmentally friendly. The ratio of corn flour to plastic depends on the product requirements. For a harder finish, add more corn flour; for a tougher finish, adjust the plastic ratio accordingly. However, these two materials have different properties: corn flour is hydrophilic, while plastic is hydrophobic, so mixing them directly can easily cause them to break apart. Add a coupling agent to act as a strong double-sided tape to secure them. Lubricant is also added to "oil" the materials, ensuring smooth operation in the machine without damaging the equipment and maximizing efficiency. Pour these materials into the high-speed mixer and thoroughly mix them, which is key to consistent quality.

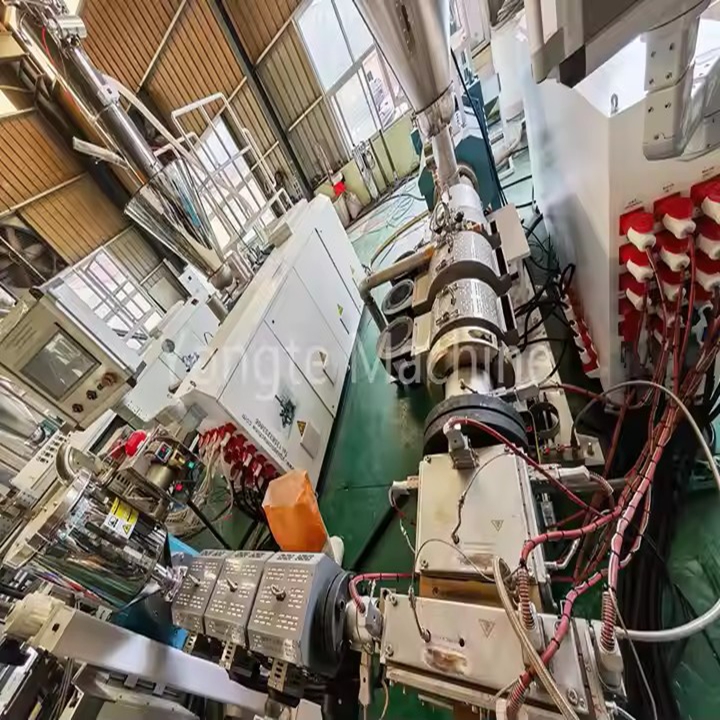

The strength of Yongte Plastic Machinery lies in its high degree of automation, which saves time and effort. Simply feed the mixed materials in, and the machine itself runs. The key lies in extrusion plasticization: The material enters the twin-screw extruder, where the screws rotate and heat, melting the plastic into a viscous paste that evenly coats the corn flour, releasing a hot, fused strand. Molding is achieved through molds: The hot strands are precisely fed into a selected mold (you can choose the desired mold) and pressed into the shape of flooring, pillars, or lines. Shaping requires quenching: The soft, freshly extruded profiles are immediately cooled in a water tank to stabilize their shape. Finally, cutting: The cooled profiles are steadily pulled out and cut into standard lengths with a few "clicks," resulting in clean, sharp cuts.

The biggest selling point of wood-plastic composites made from corn waste is durability and ease of construction:

It is waterproof, insect-resistant, and more resistant to sun and rain than wood, making it a top choice for outdoor flooring, fencing, and flower boxes.

It can be sawed, nailed, and painted, making it as easy to process as solid wood. It also suits interior wall panels and furniture frames. The raw material is virtually free, and turning waste into products reduces pollution from incineration, significantly reducing costs. Using Yongte plastic machinery is not just about buying equipment, but about opening a new path - turning unwanted corn stalks and cobs in the fields into profitable wood plastic products, saving costs, benefiting the environment, and making a profit on both ends.