WPC floor tiles are gaining popularity, and Yongte's wood-plastic profile production lines are a focus of investors.

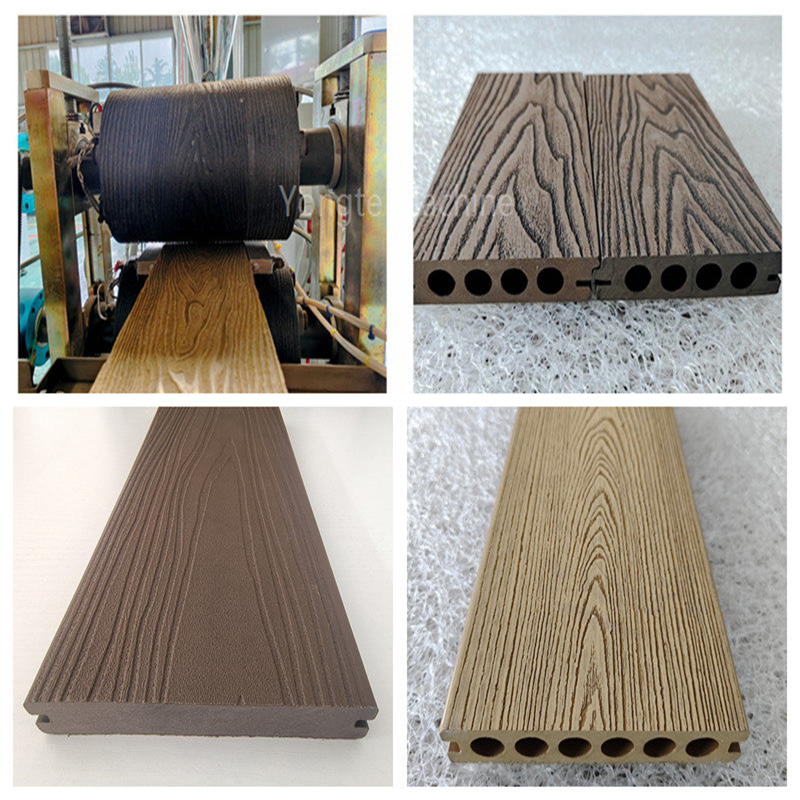

With residents' demands for higher quality of life and environmental performance in their courtyards, WPC floor tiles are experiencing rapid growth due to their excellent overall performance and green attributes. Underpinning this trend, Yongte Plastic Machinery's wood-plastic profile production lines have become core equipment for many manufacturers seeking to expand into this sector and capture market share. Compared to traditional floor tiles, wood-plastic floor tiles offer significant advantages in terms of weather resistance, anti-slip properties, ease of installation, and low maintenance costs. Made primarily of wood fiber and plastic polymers, these tiles are formed through a specialized extrusion process. They are UV-resistant, moisture-resistant, have low water absorption (less than 1%), and are frost-resistant, extending their service life by 3–5 years compared to conventional floor tiles. Their surfaces often feature a wood-like texture or anti-slip grooves, maintaining a coefficient of friction above 0.6 even in humid conditions, significantly enhancing safety for outdoor activities. The snap-on design significantly simplifies installation, allowing a single person to complete approximately 20 square meters of flooring per day. Partial replacement is also supported, significantly reducing overall costs.

Furthermore, WPC floor tiles resemble natural wood or stone in appearance, have a slightly springy feel, and require only rinsing with water or wiping with a neutral detergent, eliminating the need for tedious maintenance like waxing or painting. They are particularly well-suited for modern families seeking a beautiful and practical courtyard space. From an environmental perspective, the material, primarily made from waste wood and recycled plastic, emits no formaldehyde and is recyclable, highly consistent with the development of green buildings. They are also suitable for load-bearing applications such as rooftop gardens and terraces.

Sustained growth in end-user demand and supportive environmental policies are driving the WPC floor tile market to expand at double-digit rates annually. The market is expected to continue replacing some traditional floor tile products, demonstrating significant growth potential. In this market opportunity, the wood-plastic profile production line provided by Yongte Plastic Machinery is crucial for ensuring product quality and increasing production capacity. This line utilizes an advanced two-stage extrusion system, precisely controlling raw material ratios, processing temperature, and extrusion pressure to ensure uniform density and stable mechanical properties in the finished product, achieving high fidelity in design textures and colors, and helping customers establish market differentiation.

To meet the production demands of WPC floor tiles, including diverse specifications, custom-shaped cutting, and rapid production changeovers, this production line is equipped with modular molds and online cutting equipment, enabling flexible customization and helping companies efficiently respond to diverse orders. The entire line achieves automated continuous production, reducing manual intervention and increasing daily production capacity by over 30% compared to traditional equipment. This helps companies expand their scale and secure market orders while controlling overall costs. Regarding energy consumption, optimized heating and cooling structures and exhaust gas treatment systems enable energy-saving and low-carbon operation, highly consistent with the company's environmental commitment.

Yongte also provides full-cycle services, from installation and commissioning to operator training and long-term maintenance, to maximize production continuity and equipment stability. Currently, several companies using this production line have rapidly established advantages in the WPC floor tile market, achieving synergistic growth in both production capacity and profitability. Against the backdrop of growing demand in the WPC floor tile market, Yongte's plastic machinery production line, through its technological empowerment and service support, is becoming a key force driving high-quality expansion in the industry, providing investors and manufacturers with substantial returns and long-term development opportunities.